High Power LED

EDC Series SMD package Offered in the widest spectrum of LED emitters in the industry, ranging from 265nm λP to 1650nm λP. The new EDC Series can be used to package any LED in this spectrum. Example: the EDC850DS-1100-02 mounts a 1 x 1mm AllnGaP Die that emits at 850 λP with a typical Radiant intensity of 6000mW/sr & Radiated Power of 1400mW. UV, Visible (including White Light), or other IR Power LED Die can also be used in this small SMD leadless package. With highly durable silicone lens technology, a Thermal Resistance (Rthj) of 5K/W, and a Power Dissipation of 2000 mW, the EDC Series may be your best choice.

High Power SMBB Package can be used for food sorting machines, solar simulation, Security Cameras, ALPR /ANPR (Automatic number-plate recognition) System and Facial recognition system. Marubeni’s SMBB850DS-1100-02 (wavelength 850nm, viewing angle +/- 10 deg) gives the highest performance for ALPR /ANPR (Automatic number-plate recognition) System.

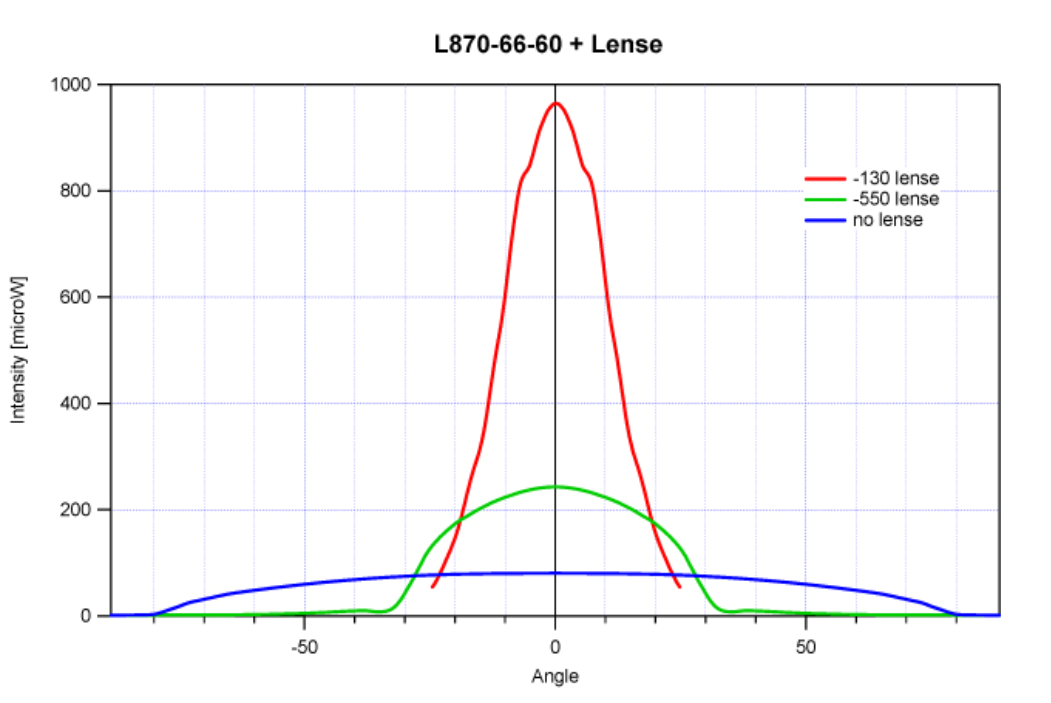

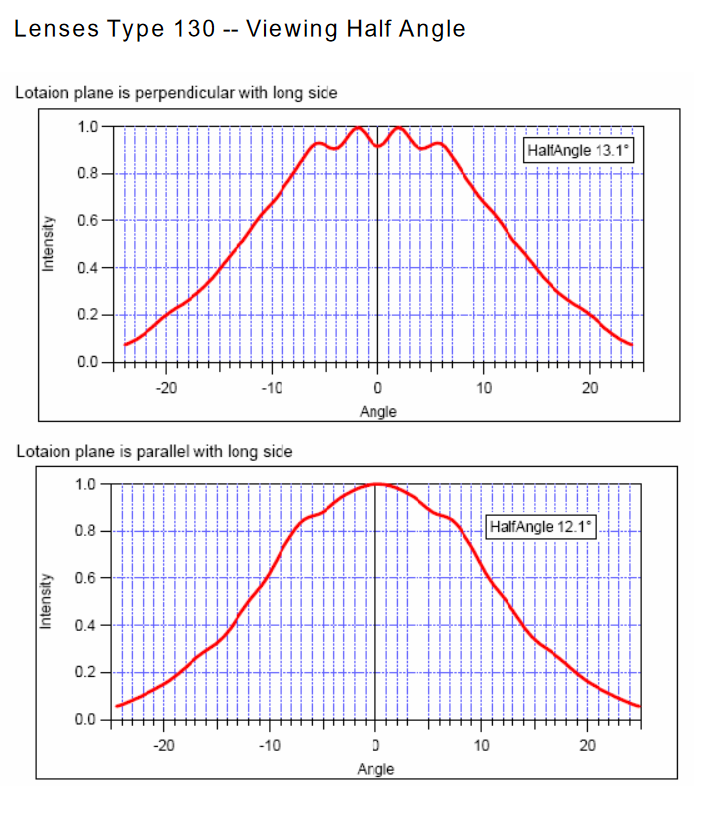

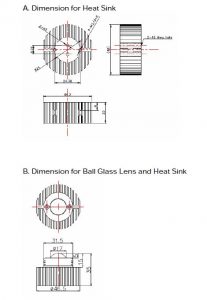

High Power illuminators consist of 60 chips mounted on a metal stem TO-66 package with AlN ceramics and covered with clear silicone and epoxy resin. These illuminators are designed to be used with proper heat sinking to improve thermal conductive efficiency. Any illuminator is also available with a heat sink and lens combination (called the 550 option), but not all 550 specifications are shown. If you need a custom part, we are willing to discuss the options; please contact us.

Loading...

Loading...

High Power Illuminators / TO-66 / LED Arrays

Tech-LED offers a range of high-power LED illuminators and arrays – including packaged LEDs in TO-66 can formats, multi-die LED modules, and pre-mounted LED boards – to serve applications that demand exceptionally intense light output. These products go beyond single-component LEDs, often incorporating multiple LED chips on a common substrate (chip-on-board or array configurations) or using heavy-duty packages like TO-66 metal cans for thermal management. The High Power Illuminator category is essentially our “extreme output” LED solutions, which deliver optical power in the range of watts (for visible light) and high hundreds of milliwatts (for IR/SWIR) in single units. They are ideal for lighting up large areas or long distances and often function as LED replacements for traditional lamps or as building blocks for lamp assemblies.

Characteristics of High-Power Illuminators and Arrays

- Multi-Chip LED Arrays: Many products in this category are COB (Chip-On-Board) arrays or multi-chip assemblies where numerous LED dies are mounted on a single substrate to act as one light source. For example, we have LED array modules with 16 chips on a 13.5 mm × 13.5 mm ceramic COB, creating effectively a single large LED emitting surface. These arrays can produce extremely high total flux – for instance, a visible COB might output thousands of lumens, and an IR COB could emit a watt or more of IR power. The chips in these arrays can be all the same wavelength for maximum intensity or a mix (for broad spectrum or tunability). By clustering chips densely, we achieve an “Ultra High Power in 1 package”, especially beneficial for SWIR where one chip’s output is low – our COB approach gets sufficient SWIR output by combining many dice.

- TO-66 and Metal Can Packages: TO-66 is a type of metal transistor can package (with two leads and a large base plate) known for its ability to dissipate heat. We mount high-power LED chips or multiple chips in TO-66 cans (or similar large metal packages like TO-5, TO-8) to create LEDs that can handle several watts of input power. These metal-can LEDs often have built-in hemispherical lenses or flat windows. For instance, an 850 nm high-power LED in TO-66 might contain four large IR chips in series, emitting a strong narrow beam IR for surveillance lighting. The robust metal package protects the LED chips and can be hermetically sealed, ensuring long life in harsh conditions. These are often used in military or outdoor systems needing durability and high output.

- Integrated Reflectors and Optics: Our high-power modules often include integrated secondary optics. Some COB arrays are mounted on aluminum cores with reflector cups or lenses over each chip to shape the overall beam. Others might come with a removable lens cover that turns a Lambertian COB into a focused beam. In the Point Source LED sub-category (closely related), we offer single-chip emitters in reflective metal packages that emulate a point light source – these have very small emission areas but in a highly collimated output due to an integrated parabolic reflector or ball lens, useful for fiber coupling or searchlights. Essentially, the High Power Illuminator line provides not just raw LED chips, but LED light engines with optical features to direct light where it’s needed – for example, collimated IR LED modules for CCTV that can illuminate a narrow field 100+ meters away.

- Heat Management Solutions: High-power LED units generate significant heat, so they are built with materials and structures to efficiently remove heat. This includes large thermal pads on COBs, copper-core TO cans, and often pre-mounted configurations on heat-spreader substrates. Tech-LED’s high-power modules can typically be mounted directly to additional heatsinks. We provide guidelines or even active cooling options if necessary. For instance, a high-power SWIR LED array might come on a copper core PCB that the user screws onto a heatsink with thermal grease. The design ensures that even when delivering an optical output at 1450 nm for solar simulator or semiconductor inspection usage, the junctions stay within safe temperatures. We also often bin and test these at high drive currents to guarantee reliable operation at spec. In short, these illuminators are engineered as “ready-to-use” powerful light sources, not just components.

- Modularity and Custom Assemblies: We understand high-power needs are application-specific, so many of our illuminator products are modular. We can configure arrays in different shapes (linear bars, rings, clusters) depending on the use-case. For example, for an ALPR (license plate reader) system, we might provide a ring illuminator consisting of multiple high-power IR LEDs arranged in a ring PCB that can mount around a camera lens – basically a custom array designed to flood a car license plate with IR at 810 nm for clear night imaging. Or for machine vision, a customer might need a flat, large-area backlight panel; we can populate a matrix of our high-power LEDs on a metal-core board sized to their machine vision station, yielding a bright, uniform backlight. This modularity and willingness to do custom high-power assemblies mean the client gets a solution that’s tailored to their system, often saving them from having to engineer their own multi-LED lamp from scratch.

Applications of High-Power LED Modules and Illuminators

These high-power LED solutions are deployed where maximum light (or infrared) is required. One prominent application is solar simulation and panel inspection. In solar panel manufacturing, EL/PL (electroluminescence/photoluminescence) tests require strong IR illumination to provoke emissions or to inspect cells. Our high-power IR LED arrays in the 800–1000 nm range can act as illumination sources to simulate sunlight or induce panel luminescence. They are safer and longer-lived than high-intensity flash lamps traditionally used. Additionally, specific SWIR LEDs (like 1200 nm, 1300 nm) are useful for silicon wafer inspection and solar cell inspection, because they penetrate silicon and reveal defects. We supply high-power SWIR LED modules that can flood a wafer or cell with the needed wavelength uniformly. In fact, for silicon wafer inspection systems, arrays of our 1300 nm and 1450 nm COB LEDs are used to detect internal cracks or impurities, as those wavelengths pass through silicon where visible light cannot.

Another key area is LED lighting for machine vision and industrial imaging. Our high-power visible white COBs and multi-color arrays serve as strobe lights or continuous illuminators on production lines. For example, an automated optical inspection (AOI) machine might use a bright ring light of white COB LEDs to examine PCB assemblies for solder defects. Tech-LED’s COB (Chip-On-Board) products in this category deliver extremely uniform and bright light ideal for camera systems. Moreover, because we can mix wavelengths, some machine vision setups use our bi-color illuminators (like white + IR) to capture different image features under different lighting.

In security and night vision, high-power IR illuminators are critical. We provide LED array illuminator boards that output invisible IR for CCTV cameras monitoring large areas like parking lots, perimeters, or critical infrastructure. These often use numerous 850 nm or 940 nm high-power LEDs mounted on a panel with an included lens array to shape the beam (e.g., 30° for long range or 60° for wide angle). Compared to older designs with dozens of 5mm through-hole IR LEDs, our modern high-power LED illuminators are more compact, reliable, and powerful. They allow surveillance cameras to see clearly at 100+ meters in darkness. Additionally, vehicle-mounted IR searchlights for police or military can leverage our TO-66 IR LEDs for a rugged, shock-resistant IR spotlight (unlike fragile IR lamps).

Automotive and transportation use high-power LED modules for both sensing and lighting. For instance, adaptive driving beam headlights or matrix headlights incorporate LED arrays (like our COBs) to create patterns of light that adjust dynamically. We supply bright LED arrays (white or specialized spectra) that can be segmented for such applications. Also, LiDAR and night vision on vehicles may use our high-power 905 nm or 940 nm pulsed LED emitters (some designs prefer LED over laser for eye safety and wider field). A powerful LED array spread across a front grille can flood the road ahead with IR for an IR camera to detect pedestrians or animals in night conditions beyond the reach of headlights.

Finally, scientific and specialty lighting often demands the kinds of wavelengths and powers we offer. In horticulture, high-power LED boards mixing deep red, far red, blue, etc., are used to stimulate plant growth – our multi-wavelength COBs can be tailored to the exact spectrum with high intensity. In aerospace or military optical systems, robust point source LEDs in TO cans might be used in rangefinders or secure optical communications (for example, a TO-66 1550 nm LED as a broad-beam transmitter that’s eye-safe and covert). And for research, having a broadband array (like a combination of UV, visible, IR high-power LEDs) allows for simulation of various environmental lighting conditions or spectroscopy light sources.

In summary, Tech-LED’s High Power Illuminator offerings are designed to meet the most demanding lighting requirements across industries – wherever a standard LED isn’t enough, we bring together many LEDs or special packages to create a powerhouse light source. From brightening the night for cameras, to simulating sunlight for testing solar cells, to providing the backbone for next-gen automotive lighting, these solutions underscore our commitment to pushing LED technology to new heights of output and utility. We pride ourselves on working closely with clients to customize these high-power solutions – delivering the right combination of wavelength, power, beam shaping, and form factor to perfectly integrate with the end application.