micro UV-LED chip for microLED display

The full-color flat panel display uses LED technologies. OLED had taken the lead in the most recent years and it’s now shifting to microLED. There are two mainstream microLED technologies, 3 microLED Display and Blue + RG Display, which unfortunately have disadvantages for mass production of flat panels. Our technology has overcome those disadvantages and will make the most efficient display system.

These are the key disadvantages of these 3 older technologies:

- OLED Display: Short lifetime and poor durability against heat

- 3 microLED Display: Complicated mounting process due to three (red, blue, and green) different structures

- Blue + RG Display: Poor efficiency and color balance

In contrast, our new technology. UV + RGB Display, has the following advantages:

- Long lifetime

- Excellent efficiency

- Easier mounting process

- Great color balance

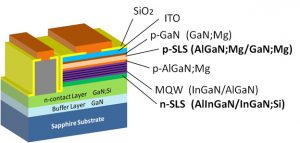

Blue micro-LED can achieve the full-color display by exciting red and green phosphors with blue LED . All micro UV LED chips have the same structure, which makes the mounting process and the device control much easier compared to the full-color display with three LEDs (red, green and blue). Luminous efficiency is doubled when fabricating micro UV LED chip with SLS structure in both n and p layer (Patent pending).

Samples are available upon request. Please click here to contact us.

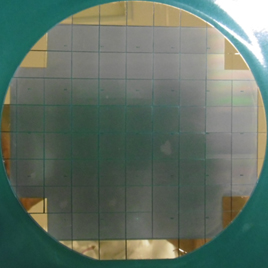

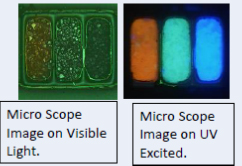

Micro UV-LED wafer

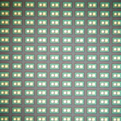

Micro UV-LED chip

Image of UV light

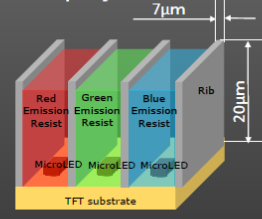

RGB element structure images by V-Technology (Japan)

|

|

|

Loading...

Loading...

MicroLED Display Technology – UV LED Solution for Next-Gen Displays

MicroLED is an emerging flat-panel display technology that uses microscopic LEDs as individual pixels. It promises high brightness, long lifetime, and wide color gamut without the drawbacks of OLED (such as short lifespan or burn-in). However, manufacturing full-color microLED displays at scale has proven challenging. Each pixel in a conventional RGB microLED display requires tiny red, green, and blue LED chips to be precisely fabricated and placed, which is a complex and costly process. Tech-LED (Marubeni) addresses these challenges with an innovative micro UV-LED chip solution that simplifies pixel fabrication while achieving excellent color performance.

Currently, there are two mainstream approaches to building full-color microLED panels, each with limitations:

RGB microLED (three LEDs per pixel)

Using separate red, green, and blue micro-LED chips for each pixel can produce excellent color directly, but it requires handling three different LED materials/structures and a complex mass-transfer process to place billions of sub-micron chips. This approach faces low yield and high cost in mass production.

Blue + phosphor (blue LED with red/green conversion)

This method uses a blue microLED for each pixel, combined with red and green phosphor or quantum-dot converters to generate the other colors. It reduces the number of LED chips per pixel to one, simplifying assembly. However, relying on a single blue emitter can lead to poor color balance and lower efficiency (since converting blue to red/green light incurs losses), and blue LEDs can suffer from longevity issues under high brightness.

Tech-LED’s solution is a new “UV + RGB” microLED display architecture that overcomes the above drawbacks. In our approach, each subpixel is based on a deep UV micro-LED chip with a suitable conversion material to produce red, green, or blue light. Because all the LED chips are of the same type (UV-emitting gallium nitride microLEDs), the fabrication and transfer process is uniform across the entire display. This drastically simplifies manufacturing compared to handling separate RGB LED types. It also improves yield and allows all subpixels to have identical electrical and thermal characteristics.

Longer lifetime

UV microLED chips exhibit excellent durability and minimal degradation over time, avoiding the quick blue-aging problem of OLEDs and traditional blue LEDs. Our UV-based displays maintain brightness and color accuracy for a longer operational life.

High efficiency

The UV + phosphor approach achieves outstanding luminous efficacy. By optimizing phosphor formulations for red, green, and blue emission under UV excitation, we attain efficient color conversion with minimal energy loss. In fact, our proprietary micro-UV LED design uses a special super-lattice structure (SLS) in the semiconductor layers, roughly doubling the internal quantum efficiency of the LED (patent pending). This advancement allows our microLED pixels to achieve significantly higher brightness at a given power level, elevating overall display performance.

Simplified assembly

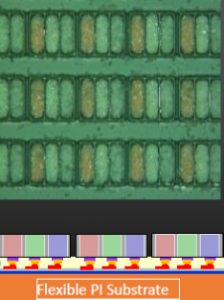

Using one type of microLED chip for all colors means easier mass transfer and integration. Manufacturers can bond arrays of identical UV LEDs onto a panel backplane, then simply apply different nano-phosphor coatings for each color subpixel. This reduces complexity and misalignment issues, paving the way for scalable production of large microLED screens.

Excellent color balance

Our UV-driven pixels achieve a wide color gamut and precise white balance. The red, green, and blue output can be fine-tuned via phosphor properties to ensure each color channel is proportionally balanced. This mitigates the color inconsistency issues seen in blue + phosphor systems and results in vivid, accurate colors that meet or exceed NTSC/P3 gamut standards.

In practice, a microLED display built with Tech-LED’s UV chip technology can deliver the best of both worlds: the simplicity of single-color LED assembly and the high image quality of an RGB LED display. The UV micro-LED chips are all identical in structure, making it feasible to mass-produce high-resolution panels for televisions, smartphones, AR/VR headsets, and large-format digital signage with lower defect rates. In addition, because UV micro-LEDs can be fabricated at very small sizes while maintaining efficiency, they support extremely high pixel densities – crucial for tiny augmented-reality (AR) or virtual-reality (VR) microdisplays, as well as for achieving 4K/8K resolution on large TV panels. Moreover, the smaller chip size of UV LEDs (since they emit in shorter wavelengths) allows for very high pixel densities, enabling ultra-fine resolution displays.

Tech-LED has demonstrated microLED pixels using this UV + RGB approach with impressive results. Our micro UV-LED chips are available as samples for development and prototyping. We continue to optimize the technology, and our experts are ready to collaborate on integrating these microLED solutions into new display products. With our cutting-edge UV microLED innovation, display manufacturers can accelerate the path toward affordable, high-performance microLED screens that will revolutionize the viewing experience. For any inquiries or to request sample chips for evaluation, please contact Tech-LED.