Surface Mount LED

SMD LEDs: Surface Mount Device or “Chips” utilizing leaded or lead-less package styles was another innovation in LED package styles. This type of package did not require PTHs. Plastic Leaded Chip Carriers are popular with sizes based on surface mount electronic formats such as chip capacitors. This format was also incorporated into devices with more than 1 LED die, including 3-die RGB formats with 4 I/O. With the advent of chip-scale packaging, which is a leadless SMD format particularly utilized for Power LEDs, back-side solder pads are used for I/O, as well as a “thermal pad” that transfers the heat to the PCB, with the PCB typically having a number of PTH used for thermal purposes of transferring the generated heat to the backside of the PCB.

Mid-Power LEDs: This style LED typically utilizes a SMD format. It is based on 500 x 500 micron or similar sized die, usually 1 die/package.

High Power LEDs: This style LED typically utilizes a SMD format. It is based on 1000 x 1000 micron or similar sized die, usually 1 die/package.

Marubeni’s SMBB850DS-1100-02 (wavelength 850nm, viewing angle +/- 10 deg) gives the highest performance for ALPR /ANPR (Automatic number-plate recognition) System.

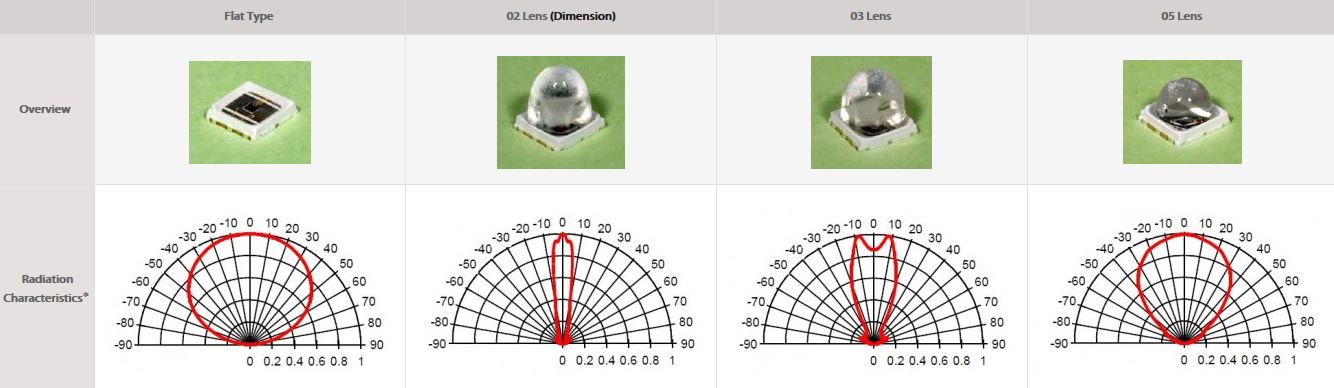

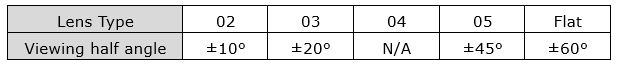

Lens Type and Radiation Characteristics

*e.g. SMBB760D Series

SMBB (5.0 x 5.0 x 1.0)

SMT (3.5 x 2.8 x 1.8)

SMC (3.0 x 2.0 x 1.1)

EDC (3.5 x 3.5 x 2.0)

S3B (3.0 x 3.0 x 0.6)

Mini Top LED

Loading...

Loading...

Surface Mount LEDs

Our surface-mount LED category encompasses a wide array of SMD packages – from industry-standard plastic LEDs to advanced ceramic high-power devices – all designed for automated assembly and compact integration. Tech-LED’s SMD lineup covers the full spectral range (UV 365 nm through IR 1650 nm) in miniature, board-mountable formats. By using modern surface-mount technology (SMT), these LEDs can be reflow-soldered onto PCBs, enabling high-density layouts and cost-effective mass production. We offer common SMD footprints like 3528 and 5050 (for example, a 3.5×2.8 mm PLCC-2 LED or a 5.0×5.0 mm PLCC-6 package), as well as proprietary ceramic packages that maximize optical output and thermal performance. Our surface-mount LEDs come in single-color and multi-chip configurations, including RGB or multi-wavelength emitters in one package. This means you can find custom multi-wavelength LED modules – multiple LED dice under one lens – in an SMD form factor for sophisticated applications.

Advantages of Tech-LED Surface-Mount LEDs

- Compact Size & Low Profile: SMD LEDs have no wire leads, allowing them to be extremely small and flat. They sit only a few millimeters high or less, ideal for space-constrained designs. Even high-power SMD packages (with integrated lenses) maintain a low profile for use in thin devices. This compactness enables LED deployment in smartphones, wearable devices, and dense LED arrays that wouldn’t be possible with through-hole parts.

- Automated Assembly: Surface-mount LEDs are designed for pick-and-place machines and reflow soldering, supporting high-volume manufacturing. Their standardized pads and tape-and-reel packaging let you seamlessly integrate Tech-LED components into SMT assembly lines. This results in lower assembly costs and consistent placement accuracy, which is critical for products like LED displays or lighting panels where hundreds of LEDs must be aligned. Our SMD LEDs have durable ceramic or PLCC housings that withstand reflow temperatures without degradation.

- Wide Range of Options: Tech-LED offers SMD LEDs in many package families. For low- to mid-power needs, we have PLCC-2 and PLCC-4 packages (e.g. 3528, 3535, 5050 sizes) commonly used for indicators and lighting. For higher power, we provide ceramic substrates (such as our 3.5×2.8 mm and 5×5 mm series) that handle greater currents and heat. Lens options include integrated domes for narrow beams or flat-top clear windows for wide-angle emission, giving designers control over beam spread. Color offerings span deep UV, violet, blue, true green, amber, red, and infrared, including specialty peaks like 365 nm, 590 nm, 730 nm, 850 nm, 940 nm, etc. If you need a specific wavelength bin or intensity bin, we can accommodate that as well.

- High-Power and Multi-Chip Capability: Unlike older SMD LEDs limited to single dies, our advanced ceramic SMD packages can integrate multiple chips. For instance, we offer multi-chip SMD LEDs that combine different wavelengths in one package (useful for multi-color illumination or spectroscopy), as well as packages with chips connected in series or parallel for higher voltage or higher output. We also provide 850 nm and 940 nm SMD IR LEDs in high-power versions for illumination – these compact IR emitters can output tens of milliwatts and are used in camera lighting and depth sensors. An example is our 850 nm SMD LED in a 3.5×2.8 mm ceramic package, which delivers high radiant intensity in a small footprint.

- Excellent Thermal Management: Our high-power SMD LEDs use ceramic or metal-core substrates that efficiently conduct heat away from the LED junction. This allows them to be driven at higher currents for greater brightness. Many packages are designed to be mounted on metal-core PCBs or with thermal vias to heatsinks. By keeping junction temperatures low, we ensure stable output and long lifetime even for infrared and UV LEDs which are heat-sensitive. For example, our SMD UV LEDs (365 nm, 385 nm, etc.) are built on aluminum nitride ceramics to handle the heat of UV operation while maintaining high UV output.

Applications of Surface-Mount LEDs

Because of their size and versatility, surface-mount LEDs find use in nearly every industry today. Consumer electronics rely on SMD LEDs for indicator lights, display backlighting, camera flash, and face recognition illumination. Many smartphones use an 850 nm IR SMD LED for facial recognition or eye-tracking, as it sits invisibly behind the screen or beside the front camera. In automotive, SMD LEDs are used for interior illumination, dashboard indicators, and even headlamp or tail lamp arrays (where high-power SMDs are clustered for brighter output). The automotive requirement for vibration resistance and automated assembly makes SMD LEDs ideal.

Machine vision and industrial sensing heavily use our surface-mount IR and UV LEDs. For example, an array of SMD 940 nm IR LEDs can be mounted around a camera lens on a PCB to serve as a night-vision illuminator or an eye-tracking system illuminator. Because SMD LEDs can be densely packed, they enable high-power IR illuminator panels much smaller than those using discrete through-hole lamps. Similarly, UV SMD LEDs (e.g. 365 nm in 3535 package) are integrated into compact PCB-based UV curing lamps and counterfeit detection modules.

In medical and wearable devices, surface-mount LEDs provide light for diagnostics and monitoring. For instance, 660 nm red and 940 nm IR SMD LEDs are used in smartwatches and finger clips for pulse oximetry (measuring heart rate and blood oxygen). Their tiny size and low power consumption allow integration into wearable sensors that contact the skin. We also offer 530 nm green SMD LEDs for PPG heart-rate sensors, as green light provides strong contrast for blood-flow detection in fitness trackers. These LEDs are chosen for their precise wavelength and efficiency in penetrating tissue, enabling vital sign monitoring in consumer health tech.

Lighting and displays benefit from SMD LED technology as well. Our high-brightness SMD LEDs (like 5050 RGB LEDs or 3535 white LEDs) are used in LED strip lights, signage, and full-color displays. The ability to place thousands of SMD LEDs in a matrix is the backbone of indoor LED screens and outdoor billboards. Tech-LED’s SMD portfolio includes calibrated RGB LEDs for uniform color in displays, as well as high CRI white SMD LEDs for architectural lighting (using blue LEDs with phosphor in standard packages).

In summary, surface-mount LEDs from Tech-LED deliver space-saving design, high reliability, and spectral breadth. Whether you’re building a compact IR sensor, a wearable medical device, or a large LED video wall, our SMD solutions provide the performance and ease of integration you need. With options ranging from standard low-power indicator LEDs to custom multi-wavelength SMD modules, we can support your specific application with the right surface-mount product.