EDC (3.5 x 3.5 x 2.0)

Marubeni launches the new Power EDC Series SMD package platform. Offered in the widest spectrum of LED emitters in the industry, ranging from 260nm λP to 1600nm λP. The new EDC Series can be used to package any LED in this spectrum. Example: the EDC740D-1100 mounts a 1 x 1mm AllnGaP Die that emits at 740 λP with a typical Radiant intensity of 440 mW/sr & Radiated Power of 1040mW. UV, Visible (including White Light), or other IR Power LED Die can also be used in this small SMD leadless package. With highly durable silicone lens technology, a Thermal Resistance (Rthj) of 10K/W, and a Power Dissipation of 2000 mW, the EDC Series may be your best choice.

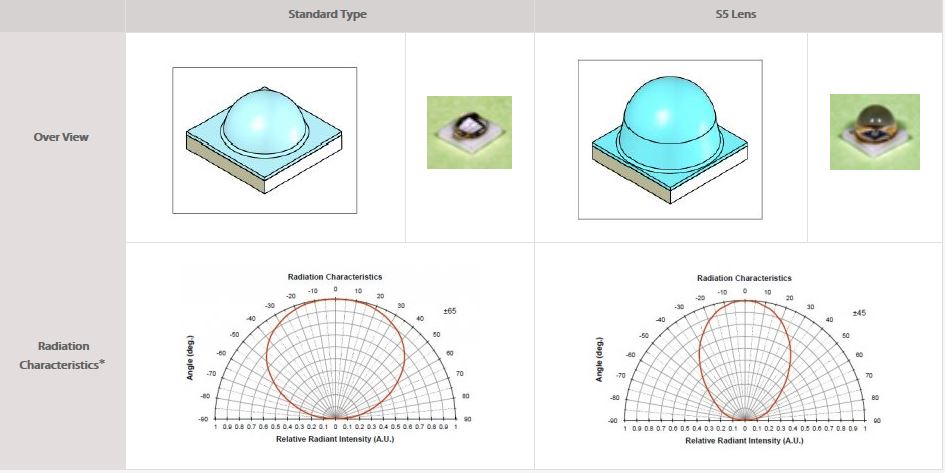

Lens Type and Radiation Characteristics

∗ e.g. EDC850DS Series

Loading...

Loading...

EDC Series

The EDC series is Tech-LED’s family of high-power surface-mount LEDs in a mid-size 3.5 mm × 3.5 mm ceramic package. EDC stands for a compact yet robust LED design that bridges the gap between our smaller SMT devices and the larger SMBB multi-chip modules. Despite its modest footprint (3.5 mm square), the EDC package is engineered for power – it can drive one or multiple chips at higher currents, and it often includes an integrated lens to focus the output. The EDC family is known for its versatility: these LEDs can be configured with various narrow or wide beam optics and are available across a wide range of wavelengths. In essence, the EDC series provides high-output, tightly controlled light from a package small enough for dense PCB layouts.

Features of EDC High-Power LEDs

- 3.5 mm Compact High-Power Package: The EDC package measures about 3.5 × 3.5 mm with a low height, making it significantly smaller than typical high-power LED packages. This compact size allows designers to use EDC LEDs in applications where board space is limited but high light output is needed. For instance, you can create an array of many EDC LEDs for even illumination while still fitting within a tight enclosure. The package is a ceramic substrate, which provides electrical insulation and efficient heat spreading for the LED die(s).

- Multiple Lens Options (Narrow to Wide): Tech-LED’s EDC series comes with a variety of molded lenses to shape the emission. We offer narrow-beam EDC LEDs with lensing that produces beam divergences like ±10°, ±16°, or ±20° – these are excellent for spotlighting or for coupling into optical systems (like sensors or fiber optics). We also have wider angle EDC variants (±45°, ±60°) for general illumination or when a broad flood is required. The lenses are directly integrated into the LED package, eliminating the need for external optics in many cases. This built-in flexibility means one can select an EDC LED part number that best matches the optical requirement of the project, be it a focused beam or a wide coverage.

- High Current Drive & Thermal Path: EDC LEDs are built to be driven at high currents (several hundred mA) if needed. The LED die is mounted on a thermal pad that solder-connects to the PCB, providing a low thermal resistance path. Thus, even at high drive currents, heat is effectively drawn into the board (especially if using metal-core or thermally via’d boards), allowing the EDC to maintain performance. Typically, an EDC LED can output on the order of 100–300 mW of optical power (depending on wavelength and lens) when driven at its rated current – making it much brighter than standard indicator LEDs. For example, our 850 nm EDC IR LED can output pulses of high IR power suitable for time-of-flight sensors or ALPR (automatic license plate recognition) systems.

- Multi-Chip and Custom Configurations: While many EDC implementations use a single high-power chip, the package can also accommodate multi-chip configurations (usually 2 or 3 smaller chips) for either increased output or multi-wavelength output. The EDC family supports multi-chip arrangements with a wide variety of lens options. This means we can customize an EDC LED to say, include two different IR wavelengths in one package (useful for sensors that perform differential measurements), or double up the same wavelength chips to double the flux. The ability to customize within the EDC form factor gives designers a lot of freedom – you can essentially design a mini high-power LED module with your required characteristics (wavelength, power, beam) and still get it in a single compact SMD component that’s easy to place on a board.

- Available in UV, Visible, IR, SWIR: Tech-LED offers the EDC series across our entire wavelength span from UV 365 nm to IR 1550+ nm. This is a standout feature – many mid-size LED packages in the market are limited to visible light, but we provide UV versions (with special lens materials that won’t yellow under UV), as well as SWIR versions up to 1300–1550 nm range. For instance, our EDC 940 nm LED is popular for machine vision and surveillance (as a small yet powerful IR illuminator), and we also have EDC 365 nm and 385 nm UV LEDs used in portable curing devices. Having one package style spanning so many wavelengths allows a design team to use a consistent footprint and thermal design while only changing the LED chip, which simplifies development of multi-spectral systems.

Applications of the EDC Series

The EDC high-power LEDs find use in scenarios where one needs a combination of high light output and compactness. One key application area is industrial sensing and sorting. For example, in optical sorting of plastics or food, you might require strong illumination at specific bands (say 1450 nm to detect water content, or 905 nm for certain plastics). EDC series LEDs provide those wavelengths in a small form factor that can be arrayed around conveyor belts or inspection windows. Their narrow-beam versions can concentrate light to penetrate deeper or highlight subtle differences in materials. In fact, an array of EDC 1450 nm LEDs can be mounted around a production line to help identify moisture or oil on products (taking advantage of water’s absorption at that wavelength), with each LED’s beam tuned to cover a specific spot without a lot of spillage.

Another application is in compact imaging devices, like portable UV lamps for forensic analysis or compact fiber-optic illuminators. An EDC UV LED (e.g. 375 nm) with a narrow lens can act as a point source to inject UV light into a fiber or a narrow beam for inspection lighting. Because the package is small, multiple EDC LEDs of different wavelengths can be clustered to create a combined illuminator. For example, a scientific instrument might use a cluster containing an EDC UV, an EDC green, and an EDC IR LED, each chosen for a particular analytic purpose, to sequentially illuminate a sample. The small size and uniform package format simplify mounting these together with a common heatsink or optics.

In the medical device realm, EDC LEDs are useful for any portable or handheld tool that requires significant light. Consider a vein finder device: it shines NIR light (~850 nm) on a patient’s skin to visualize veins. A few EDC 850 nm LEDs in a handheld ring can provide the high-intensity, focused IR light needed, but keep the device small and battery-operated. Similarly, endoscopic and surgical lighting can leverage EDC LEDs – their high power and small size mean they can be fitted into endoscope tips or surgical instruments to provide illumination inside the body. The EDC’s extreme compactness combined with high power was specifically noted as enabling new possibilities in medical devices, such as smaller endoscopes with integrated high-brightness lighting. In endoscopy, a tiny 3.5 mm LED that outputs intense light is invaluable for improving image clarity while keeping the instrument minimally invasive.

Automotive sensors also use EDC LEDs. For instance, many modern cars have driver-monitoring systems (DMS) that use IR illumination to track the driver’s eyes. These typically require a small IR LED with decent power – an EDC 940 nm LED with a 20° lens can be embedded in the dashboard or steering column to shine IR on the driver’s face for the IR camera, without being visible or taking much space. The robust ceramic package ensures reliability over the automotive temperature range. EDC LEDs at 905 nm are also used in some LIDAR or ranging systems in vehicles for obstacle detection (as short-range pulsed sources).

In summary, the EDC series provides a versatile high-power LED solution when you need something stronger than a standard SMD LED but smaller than typical multi-chip modules. Its small footprint, lens flexibility, and broad wavelength availability make it a go-to choice for designers of advanced lighting and sensing systems. From handheld medical tools and wearable tech to industrial inspection and automotive sensors, the EDC series delivers reliable, high-intensity light in a miniature package that can truly innovate product designs.