SWIR LED

Marubeni is proud to present its new line of High Power SWIR LEDs.

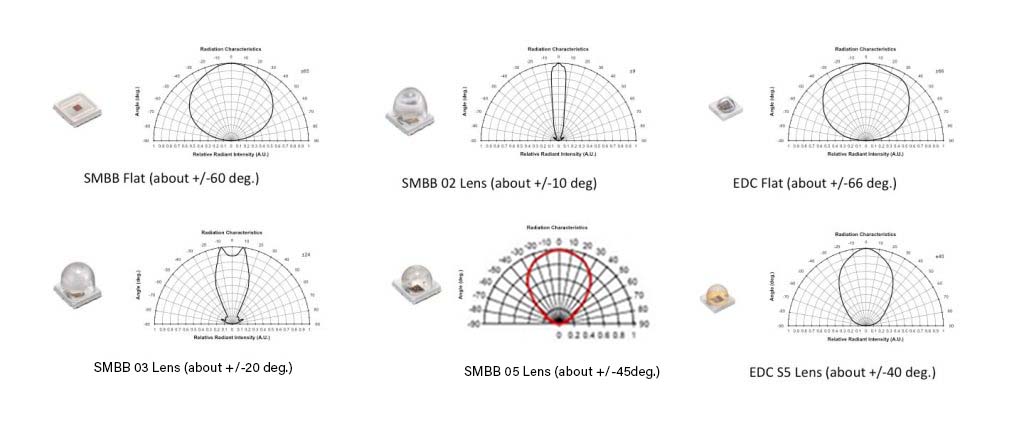

Our SWIR LEDs feature the highest power in today's market. Various lenses are available to meet your specific viewing angle requirements (+/-10 degrees - +/-60 degrees), including our ultra-sharp 02 lens which is a rarity in the market. Other advantages include:

- High power – highest in the industry

- Excellent stability over time (life characteristics)

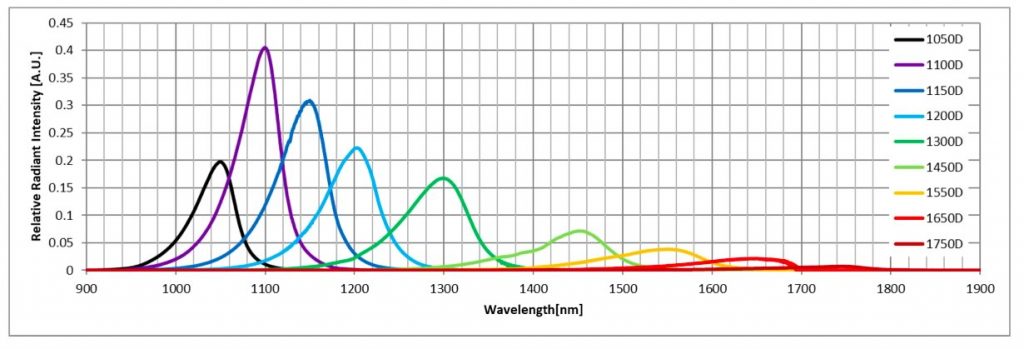

- Various wavelengths available in a wide range (1050-1750nm)

- Narrow peak wavelength tolerance (+/-20nm)

- Custom wavelengths are available based on your specific requirements

SWIR (Short Wavelength Infrared) LED features:

- Light absorption of specific substances (Water, protein, alcohol, fatty acid, glucose, etc.)

- Applications: Grain Inspection, Vital Sensor, Medical devices, Road Surface Freeze Sensor

- Silicon wafer/substrate transmission

- Applications: Solar Panel Inspection, Si Device Inspection

- Water vapor and fog transmission

- Applications: Night Vision, Security Camera Lighting

- Light source of SWIR wavelengths (1050-1750nm)

- Applications: Sun simulator light source

For more information, please contact us.

Available in Various Wavelengths

*Various wavelength are available to meet your specific requirements

Available Packages and Radiation Characteristics

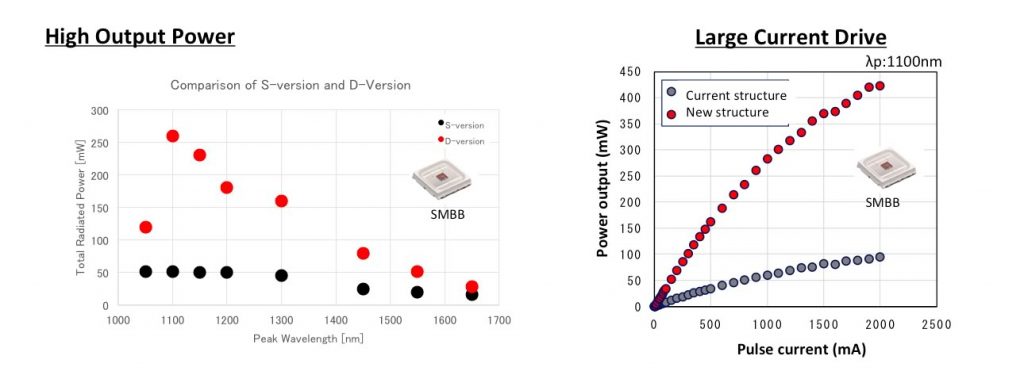

LED Performance Improvement (Compared to existing SWIR LEDs)

Highlights:

- Light output increases 2-4 times compared to older generation SWIR LEDs

- Newly designed SWIR LEDs significantly increase output power (the increase varies depending on the wavelength)

- Maintains higher light output when driven at large current

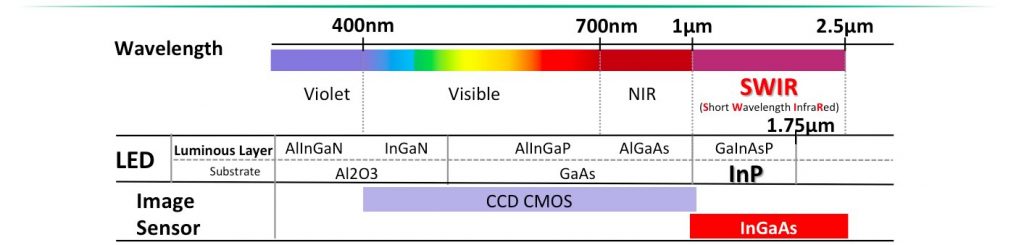

SWIR-LEDs - With Decreasing Price of the InGaAs Camera, New Applications Arise

*Various wavelength are available to meet your specific requirements

Highlights:

- Light output increases 2-4 times compared to older generation SWIR LEDs

- Newly designed SWIR LEDs significantly increase output power (the increase varies depending on the wavelength)

- Maintains higher light output when driven at large current

Loading...

Loading...

Tech-LED’s SWIR LED lineup covers short-wave infrared wavelengths from about 780 nm (just beyond red) up to 1900 nm. These are specialized LEDs that emit in the near-infrared and short-wave IR bands, which are invisible to the human eye but critically useful in many sensing, imaging, and illumination applications. We are one of the few providers of LEDs in the 1000–1700 nm range, sometimes called IR-A and IR-B bands, traditionally dominated by incandescent or laser sources. Our SWIR LEDs leverage InGaAsP and related semiconductor materials to achieve wavelengths like 1050 nm, 1200 nm, 1300 nm, 1450 nm, 1550 nm, 1650 nm, and up to 1750–1900 nm in some cases. While these LEDs have lower radiant efficiency than visible LEDs (due to material characteristics), Tech-LED has made significant progress in increasing their output power and integrating them into practical packages. We offer SWIR LEDs in discrete packages and in multi-chip modules, enabling new possibilities in industries such as optical sensing, machine vision, and telecommunications.

Distinct Advantages of Tech-LED SWIR LEDs

Unique Wavelength Availability

Tech-LED provides LEDs at wavelengths that traditionally required lasers or lamps. For instance, we have an 1050 nm LED (bridging the gap between NIR and SWIR, good for silicon detection and some night‑vision systems), 1300 nm and 1550 nm LEDs (important telecom wavelengths, now usable in short‑distance communication or sensing without lasers), and even 1750 nm and 1850 nm LEDs (useful for specialized chemical detection around 1700-1800 nm). This breadth frees engineers to develop IR systems with simpler, safer, and cheaper LED sources rather than specialized lasers.

LED Simplicity vs Lasers/Lamps

SWIR LEDs are incoherent, broad‑spectrum sources (20–50 nm bandwidth) that don’t require warm‑up or high‑voltage drivers like incandescent lamps, pose minimal eye hazard compared to lasers, and come in rugged, compact packages ideal for portable devices. You can pulse SWIR LEDs at high frequencies or modulate them for free‑space optical links without complex circuits.

Multi-Chip Power Boosting

To overcome lower single‑chip output, Tech-LED employs multi‑chip packaging with light emitting diodes. Our 8‑chip 2.9 × 2.2 mm package for light emitting diodes. or COB arrays (e.g., 16 chips on a 13 mm board) combine outputs into tens of mW. For example, our 8‑chip 1550 nm array in an SMBB package provides a practical illuminator for short‑range night‑vision, embodying our “Ultra High Power in 1 PKG (especially SWIR)” strategy.

Integration with Detectors (Optical Pairing)

Tech-LED supplies matching InGaAs photodiodes and combined packages (e.g., our two‑tone photodiode pairing Si and InGaAs light emitting diodes). We ensure compatible optical footprints – TO‑18/TO‑5 cans with lenses or fiber pigtails—for easy system integration in spectroscopy, gas sensing, and fiber‑coupled communications.

Emerging and Custom Applications

We collaborate on custom SWIR solutions: 1450 nm LEDs for early smoke detection, 1200/1300 nm LEDs for non‑invasive medical monitoring using short wavelength infrared technology, and 1550+ nm arrays for covert military illumination using short wave infrared technology. We tailor drive currents, beam profiles, and ruggedization to push SWIR LEDs from lab prototypes into real‑world deployments.

Applications of SWIR LEDs

Optical Food Sorting and Agriculture

SWIR wavelengths reveal composition through various light sources: water absorption at 1450/1950 nm in the short wave infrared spectrum., starch at 1200 nm, proteins at 940/1200 nm. Our high‑power 1450 nm arrays illuminate conveyors for InGaAs cameras to sort produce, detect aflatoxin‑infected nuts, and enable handheld grain moisture analyzers.

Moisture and Chemical Sensing

Simple 1450 nm LED + photodiode setups measure moisture via reflectance/transmission. Applications include paper‑line drying, pharmaceutical pill moisture, soil irrigation probes, and crude spectrometers using multiple SWIR LEDs to identify plastics or chemicals by characteristic absorption bands.

Medical Diagnostics and Monitoring

SWIR light penetrates deeper into tissue and interacts with biomolecules. Our 1650 nm LEDs are tested in wearable glucose monitors; additional wavelengths (e.g., 1200 nm) augment pulse oximetry for hydration or hematocrit measurements, enabling non‑invasive, medical‑grade sensing.

Telecommunications and Data

Short‑distance fiber or free‑space links can use 1300 nm/1550 nm LEDs for Mbps‑level data. Our LEDs are modulated at MHz speeds for plastic fiber transceivers, building-to-building communications, or encoded beacons for drone/aircraft navigation and identification.

Night Vision and Surveillance (Covert)

For invisible illumination, 1310 nm/1550 nm LEDs serve military and high‑end security: InGaAs‑goggle‑visible arrays light dark scenes without visible glow. We also supply 1300 nm bars and ring lights for silicon‑wafer inspection and other niche machine‑vision tasks.

In summary, Tech‑LED’s SWIR LED offerings open up a realm of IR applications historically served by bulkier, more dangerous, or more costly light sources. By providing solid‑state emitters in the 1–2 micron range, we enable optical innovation across agriculture, medicine, defense, and beyond. As SWIR imaging and sensing grow, our LEDs remain a pivotal component in fully solid‑state, mercury‑free, laser‑free systems covering every wavelength from UV through IR.

What are SWIR LEDs and their applications in machine vision?

SWIR LEDs, or short-wavelength infrared light-emitting diodes, are used in various machine vision applications due to their ability to illuminate subjects effectively in the short wave infrared range. These LEDs operate at wavelengths typically between 1000 nm and 1650 nm, allowing for enhanced imaging capabilities in low-light conditions and improved material identification.

How do SWIR LED chips differ from conventional LEDs?

SWIR LED chips are specifically designed to emit light in the short-wavelength infrared spectrum, unlike conventional LEDs that primarily focus on visible light. This unique emission allows SWIR LEDs to penetrate materials and provide better contrast in imaging applications, making them ideal for inspecting transparent or semi-transparent objects.

What is the typical output power of SWIR LEDs?

The output power of SWIR LEDs can vary based on the specific application and design. Generally, these LEDs can deliver substantial output power suitable for various applications, such as illumination in machine vision systems, where high intensity and reliability are crucial for effective imaging.

What are the benefits of using SWIR lenses with SWIR LEDs?

Using SWIR lenses with SWIR LEDs enhances imaging quality by minimizing optical losses and maximizing light gathering. These lenses are designed to work effectively in the SWIR range, allowing for sharper images and improved detection capabilities in applications like industrial inspection and surveillance.

How does the wavelength of SWIR LEDs affect their performance?

The wavelength of SWIR LEDs significantly impacts their performance in specific applications. For instance, LEDs emitting at 1100 nm may be optimal for certain types of materials, while those at 1450 nm might perform better for others. Understanding the spectral response of materials is crucial for selecting the right wavelength for effective illumination.

What role do SWIR cameras play in conjunction with SWIR LEDs?

SWIR cameras are designed to capture images in the SWIR spectrum, making them ideal for use with SWIR LEDs. When paired together, they enable high-quality imaging and inspection capabilities, particularly in applications requiring visibility through various materials or in low-light conditions.

Can SWIR LEDs be customized for specific applications?

Yes, SWIR LEDs can be customized to meet specific application needs. Manufacturers can adjust parameters such as wavelength, output power, and lens design to create tailored solutions for various fields, including machine vision, medical imaging, and security systems.

What considerations should be made when selecting a SWIR LED backlight?

When selecting a SWIR LED backlight, it’s essential to consider factors such as the desired wavelength, output power, and the specific application requirements. The illumination angles and compatibility with existing optics and sensors also play a crucial role in achieving optimal performance and reliability.

What are the reliability factors associated with SWIR LED products?

Reliability in SWIR LED products is influenced by various factors, including thermal management, material quality, and design specifications of light sources. High-quality components and proper heat dissipation techniques are vital to ensuring longevity and consistent performance in demanding applications.