What is SWIR, and how can you benefit from high-performance SWIR LEDs? How does SWIR LED work? This article will cover the basics of SWIR. We will analyze the diverse range of new opportunities that SWIR LEDs can offer.

Read on to learn about the most common uses of SWIR LEDs. The article will analyze their structure and operating principles. Moreover, we’ll look into their benefits and some possible challenges of their application.

SWIR LED – Wavelength Range

Basics of SWIR LED

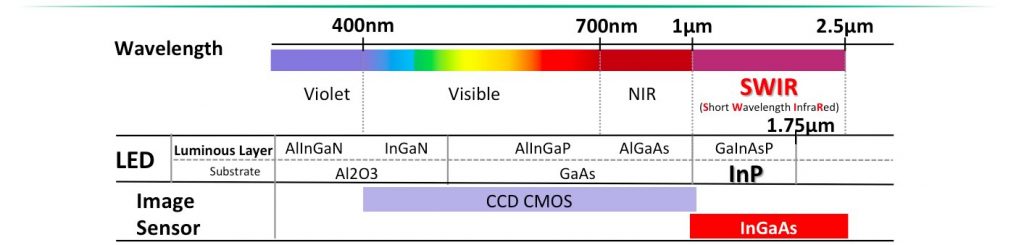

SWIR, aka Short-Wave Infrared (IR), is swiftly becoming the best option for applications that do not involve visible lighting. The wavelengths of SWIR are in the 1,050 to 2,500 nm range. That means they are invisible to the naked eye. Yet, in some cases, this field can fall between the range of visible lighting and thermal imaging.

In fact, the SWIR spectral band is close to visible light. This enables imaging qualities (e.g., resolution and contrast) while allowing it to reveal invisible elements. Simply put, the range allows SWIR LEDs to have a unique set of applications. That includes industrial, machine vision, and remote sensing purposes. It also encompasses surveillance and even ambient light applications.

Short-Wavelength infrared (SWIR) sensors and LEDs can be used for controlling image transmission through opaque materials. That includes silicon, plastics, and others. Additionally, they can unveil elements or substances such as water, collagen, lipids, alcohol, and more. High-power LEDS can also benefit various other applications, from food inspection and analysis to narcotics testing, healthcare, biomedical, and wearable devices. Overall, SWIR LEDs provide high efficiency and power with plenty of options for customization and mass production.

Operating Principle of SWIR LED

So far, SWIR LEDs have utilized low output. They have encompassed a fairly broad scope in the spectrum. Yet, new solutions have allowed a higher output in narrower spectrums that are more controlled. SWIR LEDs still have a wider spectrum and a narrower output compared to their counterparts in the visible range.

Moreover, SWIR LEDs can emit at wavelengths in the 1,050 to 2,500 nm range. They can supply high power. This makes them efficient in various new applications related to machine vision lighting. LEDs in the SWIR wavelength range have a configuration that is similar to those used in visible range applications. Their construction allows for easy and intuitive use and operation that is similar to standard LED lights.

In terms of operating principles, SWIR sensors utilize unique electronic and optical components. The primary sensors are built on chemical compositions like indium gallium arsenide (InGaAs). Moreover, many can utilize mercury cadmium telluride (MCT). Newer imagers for SWIR have also made use of quantum dot technology. However, with SWIR, the imaging capabilities and construction are dependent on the application. For example, wavelengths that are in the MWIR spectrum will benefit from MCT sensors.

Nevertheless, the prevailing technology still relies on InGaAs sensors. They are the most developed as well as the most affordable solution. They also produce high-resolution images that can interact with light much differently compared to traditional silicon imagers. This makes SWIR LEDs highly effective in applications like quality control, inspection, and sorting. They can also detect elements through fog, haze, and smoke.

Structure of SWIR LED

SWIR LEDs are commonly created out of Arsenide, Gallium, and Indium. The technology mainly uses InGaAs lattice in order to capture as well as emit light that is found in the SWIR wavelength.

As mentioned earlier, it’s crucial to choose the correct SWIR illumination and the optimal wavelength for successful results. SWIR LEDs have to follow the same principles used for the inspection of visible light.

Depending on the application, it’s possible to use singular or multiple SWIR illuminators. That includes darkfield lights, backlights, front lights (on-axis), dome lights, bar lights, ring lights, and more. When using SWIR LEDs, the most efficient results are gained with high uniformity. Plus, it requires an appropriate intensity, coverage area size, and contrast without specular reflection.

Avalanche SWIR LED Construction

SWIR avalanche photodetectors (APD) utilize reverse voltage to produce an internal gain. This allows them to have a high SNR (signal-to-noise ratio) compared to PIN diodes. It also offers faster response time, better sensitivity, as well as lower current and image noise. The spectral response of APDs is also a suitable match for the SWIR range.

What’s more, the InGaAs system seems to be ideal for SWIR detectors. Namely, it provides a standard cutoff at 1,700 nm. This covers most laser emission lines at standard wavelengths. SWIR APDs utilize avalanche gain to generate signal amplification. One of the biggest advantages of this is that they allow the use of eye-safe lasers. Plus, this also results in a sensor that doesn’t require cooling.

Advantages and Disadvantages of SWIR LED

Like we’ve said before, LEDs designed for the SWIR range can be incredibly effective in a variety of applications. They can reach vast ranges that are simply not possible with silicon-based sensors. SWIR LEDs offer unique capabilities for detection, inspection, sorting, surveillance, remote sensing, and much more.

Some of their most common uses are in the field of glass inspection, recyclables sorting, telecommunication, laser spotting, and surveillance. Other applications are found in the maritime industry, ophthalmology, spectroscopy, weapon guidance, imaging, solar inspection, and others.

All in all, one of the biggest advantages of SWIR LEDs is that they can detect chemicals and gasses. What’s more, they can operate during the day as well as at night. Again, the sensors do not require cooling, which is certainly convenient. Furthermore, they can detect any kind of invisible laser. On top of that, the use of SWIR LEDs is cost-effective.

However, perhaps the biggest disadvantage of SWIR is that it is still relatively undiscovered. It relies on capturing information in specific bands to produce the most accurate data. That’s why new users should always choose the correct wavelength for their needs. Yet, this is quite challenging because the SWIR range consists of many invisible wavelengths. While it’s possible to use hyperspectral spectrometers and other tools to find a solution that suits your application, SWIR LEDs may require a detailed trial-and-error approach.

Nevertheless, with proper use, the LEDs will produce effective lighting for a diverse range of SWIR wavelengths. They will allow users to find the ideal light source for their application. That way, users can make the most of the benefits offered by the SWIR spectrum.

Final Thoughts on SWIR LEDs

SWIR is incredibly close to the visible spectrum. That’s why it is able to offer important imaging qualities like resolution and contrast. However, it can also simultaneously capture invisible elements. It can document other phenomena that you’re not able to see with the naked eye.

SWIR LEDs are a high-performance solution. They are accurate, cost-effective, and easy-to-use. Lastly, they can open new doors and benefit many applications and industries in order to lead them into the future!

Marubeni offers a line of High Powered SWIR LEDs – more information available here.