Epitex Series Handling and Use Precautions

To ensure that the performance of the LEDs is fully demonstrated and that the LEDs are used with high reliability, the following is a list of items that must be considered when designing the system and performing the measurements.

1. Absolute Maximum Rating

Never exceed the absolute maximum rating shown in the datasheet or catalog, even for a moment. In particular, the following points should be observed:

- When operating the LED, the LED elements may be damaged by the spike current generated when the power switch is turned on and off or when the output is adjusted. Before use, be sure to check the transient characteristics of the power supply and make sure that the spike current does not exceed the absolute maximum rating of the forward current.

- If the LED element is driven beyond the absolute maximum forward current rating, the reliability of the LED element will be significantly reduced. Also, when driving the LED in pulses, make sure that the pulse current does not exceed the maximum allowable pulse current value specified in the “Forward Current – Pulse Duration” datasheet.

- The absolute maximum ratings are given at a case temperature (at the solder point) of 25°C. Therefore, the higher the temperature, the higher the maximum rating. As the temperature increases, the maximum forward current and allowable loss decrease and the operating range is limited, so design with as much margin as possible.

- There is a relationship between the junction temperature (Tj) and the thermal resistance (Rthjs), and care should be taken to ensure that the junction temperature does not exceed the absolute maximum rating as follows:

Tj = Rthjs x Pd + Ts

Each indicator has the following meanings

Tj: Junction temperature (°C)

Rthjs: Thermal resistance from junction to Ts (K/W or °C/W)

(*Thermal resistance Rthja is shown in some datasheets but should be read as Rthjs).

Ts: Solder point temperature (°C)See also.

Pd = VfxIf

Vf: Forward voltage (V)

If: Forward current (A)

Pd: Input power (W)

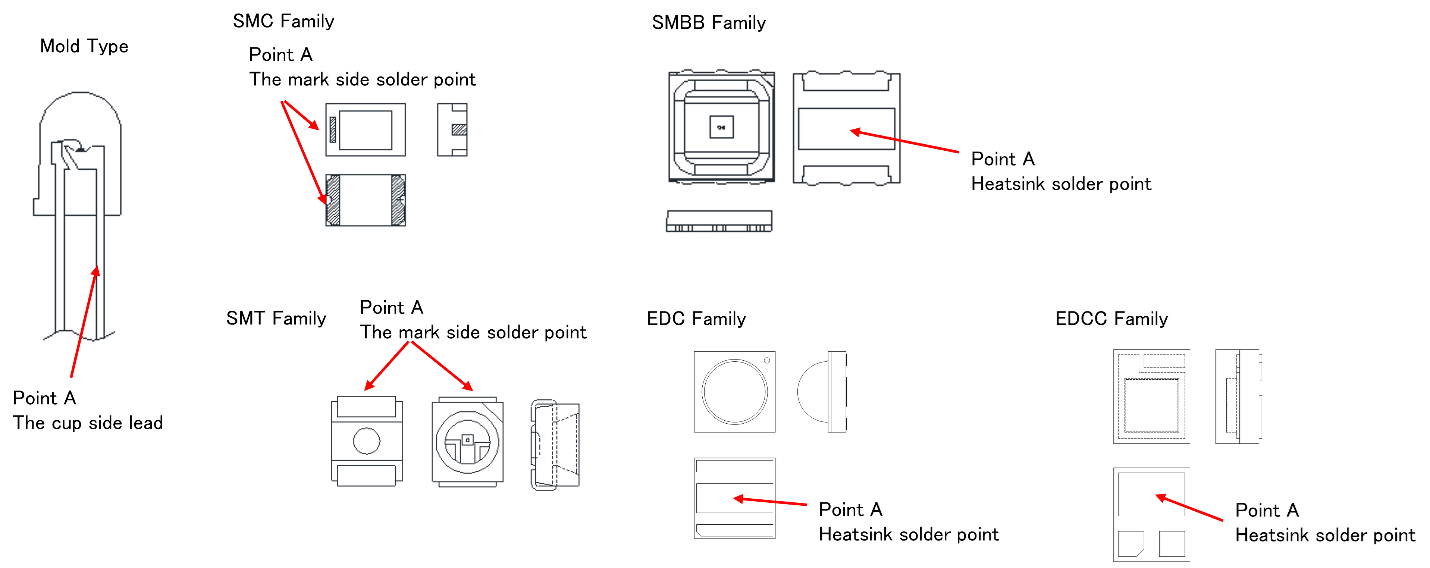

See the figure below for the location of the solder point.

- When multiple LEDs are used in a row, the Tj of each LED increases more than when used individually, adversely affecting the characteristics and lifetime of the LEDs. It is recommended to pay attention to the thermal design, including the LED mounting pitch, etc., to ensure that the prescribed Tj is not exceeded, and to verify this in advance in the actual equipment environment.

- Never apply reverse voltage in excess of the absolute maximum rating.

2. Electrostatic Discharge

LED elements may be destroyed or degraded by static electricity or surge voltage, etc. Please take care to avoid electrostatic discharge. Please take the following precautions when handling.

- To prevent destruction by static electricity charged on human body clothing, ground the human body with a high resistance (typically 500kΩ to 1MΩ) during handling.

- Ground production and inspection facilities, equipment, soldering irons, etc. in the product handling area.

- Use non-electrostatic workbenches, racks, fixtures, containers, etc. Use of conductive containers or aluminum foil is effective.

3. Packaging Specifications

3-1. SMD Type LED

SMD type LED products are equivalent to MSL4 unless otherwise specified.

If SMD-type products absorb moisture, the moisture may expand due to heat during reflow or other processes and cause delamination at the interface in the package, resulting in failure.

3-2. Mold Type LED Package Specifications

Mold type LEDs are packed in plastic bags or antistatic bags, if necessary, every 500pcs and then heat sealed.

In case of taping, the LEDs are shipped in inner boxes in units of 2,500pcs for Φ5mm and 4,000pcs for Φ3mm.

4. Storage

Observe the following storage precautions when using the product. Even if the package is unopened, do not expose the product to moisture, direct sunlight, corrosive gases or dust, rapid temperature changes, or high humidity.

4-1. For SMD type

- SMD type LED products are equivalent to MSL4 unless otherwise specified. If SMD-type products absorb moisture, the moisture may expand due to heat during reflow or other processes and cause delamination at the interface in the package, resulting in failure.

- The silica gel indicator in the moisture-proof bag and the indicator card changes from blue to red when moisture is absorbed.

- If the moisture-proof bag is unopened, the product should be stored in an environment with a temperature of 5 to 30°C and a humidity of 60% or less for a maximum storage period of 12 months.

- After opening the moisture-proof bag, finish mounting within 72 hours in an environment with a temperature of 5 to 30°C and a humidity of 50% or less.

If unused LEDs remain, place them in a moisture-proof bag with silica gel and heat seal the bag for storage.

Note that the time spent in sealed storage with silica gel after the bag is opened is not included in the 72-hour period.

Please note that the 72 hours does not include the time the LEDs are stored in an airtight bag with silica gel after opening the bag. - Once the storage period has expired, the product should be baked no more than once.

If the enclosed indicator turns red during the storage period, baking should be performed no more than once.

For baking, we recommend removing the device from the embossed carrier tape and baking in a 100°C oven for 24 hours. - Dryers used for baking should be treated with a clean interior to avoid contamination of the product.

4-2. Mold Type LED

Mold type LEDs should be stored at a temperature of 5 to 30°C and humidity of 70% RH or less, with a maximum storage period of 12 months.

Exposure to corrosive gases may cause deterioration of the leads, so please be careful about the environment in which they are stored.

5. Precautions for Use

- With a constant voltage drive, the current flowing to the LEDs may change, resulting in variations in light output. It is recommended that a limiting resistor be provided for each individual LED in a constant voltage drive.

- When LEDs are used in a parallel circuit, the current flowing to each LED is different due to the different I-V characteristics of each LED, which in turn affects the light intensity and Tj. In addition, the absolute maximum current and Tj of the LEDs may be exceeded. Please keep the above in mind and adjust the voltage applied to the LEDs by setting an appropriate limiting resistor for each LED.

- Do not apply power to the unit when the LEDs are off, regardless of the forward or reverse direction. Migration can damage the LEDs.

- The element may deteriorate if used for a long time in a high humidity environment. Please be careful when using the device for a long time in a high humidity environment.

- Do not use the product in a dewy or dusty environment. The product may malfunction if used in such an environment.

- Avoid storing or using the product in places where there are sudden temperature changes, as condensation may occur if the product is exposed to sudden temperature changes.

- Please use the product after taking measures against water, humidity and salt damage (especially for outdoor use).

- Please note that sealing resins, lenses, and packaging may turn yellow under prolonged exposure to high temperatures, which may affect the performance of the product.

- Do not look directly at the light when using LEDs at high output power or when the output light is optically focused. Your eyes may be affected. In addition, viewing strong flashing light may cause photosensitive seizures due to light stimulation. Please also consider the effects on others.

- LEDs are included in the scope of IEC62471 (Photobiological safety of lamps and lamp systems) for photobiological safety of lighting etc. Please note that even our products may fall under Risk Group 2 of IEC62471 depending on the conditions of use by the customer. If the equipment into which this product is incorporated falls under the risk group, appropriate warning signs should be displayed. Also, when using the product, take appropriate exposure control measures against eye and skin damage by wearing protective glasses, gloves, long sleeves, etc.

6. Precautions for Handling

- Use clean tweezers and gloves when handling the product. Touching the product with bare hands may adversely affect its properties. Use anti-static tweezers.

- Be careful not to apply excessive force when handling the product with tweezers.

- Be careful not to touch the seal or lens on the top of the LEDs with tweezers or the like. Doing so may cause scratches or other damage to the sealing area or lens, or may cause the wire to break or peel, resulting in no light.

- Please note that severe shocks to the product or dropping the product may cause deformation or stains on the product, whether it is in a standalone, packaged, or taped condition.

- Use a cloth moistened with isopropyl alcohol to wipe off dirt adhering to the sealing section or lens section, and do not use excessive force. Excessive force may cause damage such as scratches or failure to light due to wire breakage or peeling. Also, do not use benzene or thinner, etc., as they may damage the resin part of the product.

- We do not recommend cleaning LEDs by immersing them in isopropyl alcohol. If you must do so, please perform thorough pre-testing and ensure that there are no issues before proceeding.

- Do not use ultrasonic cleaning.

- For mounting surface mount products, we recommend using an automatic mounting machine.

- Do not shake or jiggle the tape while it is being removed from the spool, or leave it unattended for long periods of time. Do not bend the tape more than necessary.

- Do not stack boards or apply mechanical stress after mounting the product. Failure to do so may result in damage such as scratches to the sealing area or lens, or failure to illuminate due to wire breakage or peeling. Observe the precautionary markings on the product’s outer packaging when the product is shipped from our company.

7. Soldering Conditions

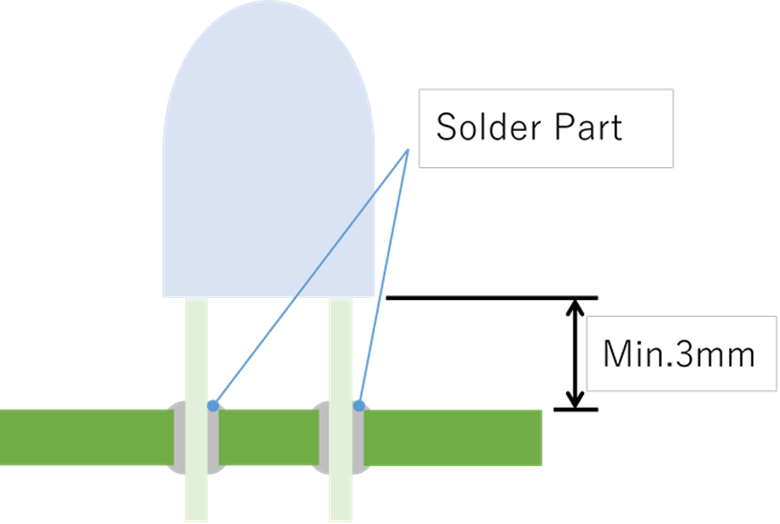

7-1. Soldering Conditions for Mold Type (Through-Hole) LEDs

Also, do not apply load to the lead frame during heating.

Solder part

Solder partDo not apply mechanical stress to the package (sealing area, etc.) when forming or cutting leads. Cracks or other damage to the package may result.

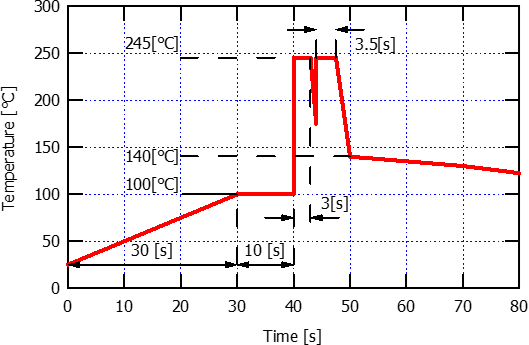

Recommended Flow Soldering Conditions

Recommended Hand Soldering Conditions

Hand soldering should be limited to one time. (*Some datasheets only mention flow soldering conditions, but hand soldering is possible).

When hand soldering, do not allow the soldering iron to contact the package part of the product. Doing so may damage the product.

| Temperature | Max. 350℃ |

| Time | 3 seconds |

7-2. Soldering Conditions for SMD (Surface Mount Device) Type LEDs

- SMD (Surface Mount Device) type LEDs are intended for reflow soldering to PWB (Printed Wiring Board).

- Reflow soldering should not be done more than once.

- Do not load the LEDs during heating.

- Hand soldering of SMD (surface mount) LEDs is not recommended.

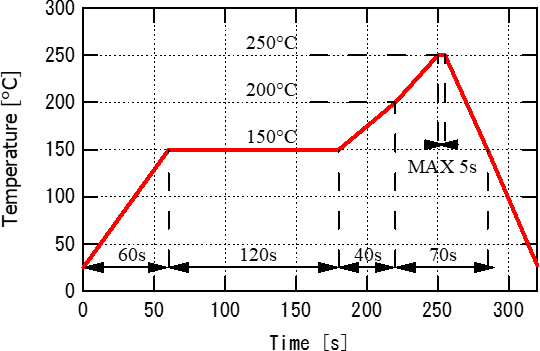

Recommended Reflow Conditions

Products are classified as MSL Level 4.

Details on Recommended Reflow Soldering Conditions

| Minimum | Recommendation | Maximum | Unit | |

|---|---|---|---|---|

| Heating rate from ambient to preheat temperature | – | 2 | 2.5 | K/s |

| Preheat temperature | 150 | 150 | 160 | ℃ |

| Heating rate from preheat temperature to maximum temperature | 1.4 | – | – | K/s |

| Max. temperature | – | – | 250 | ℃ |

| Holding time above preheat temperature | – | – | 110 | s |

| Max. temperature holding time | – | – | 5 | s |

| Cooling rate | – | 3 | 5 | K/s |

*The soldering condition profile chart is for reference only. We recommend prior evaluation based on the actual board, equipment and conditions to be used.

8. Design Precautions

- After the product is mounted on the board, bending stress may be applied when the board is split, resulting in damage to the joints of the product board. When designing the board, please consider the product mounting direction that does not apply bending stress to the board at the time of board separation.

- When this product is mounted on a printed circuit board, due to the difference in thermal expansion between the product and the printed circuit board, depending on the printed circuit board material used, excessive residual stress may occur, resulting in damage near the joint area. When designing a mounting board, consider the stress load on the product.

- When using the product, consider the heat generation; the temperature rises of the element when the LEDs are turned on varies depending on the environment in which the LEDs are used. Please consider the mounting board specifications and operating environment, and make sure that the design does not exceed the absolute maximum values of Tj.

- For ultraviolet LEDs, there is a possibility of degradation of peripheral materials due to ultraviolet light. Please check the actual operating environment before use.

- Avoid exposure to corrosive gas atmospheres containing sulfur, chlorine, etc.

- If LEDs are stored or used in an atmosphere containing corrosive gases, the die bonding agent, lead frame metal plating, etc. used for LED packages may be corroded, affecting the optical characteristics and solderability. When designing products, please pay attention to the atmospheric environment during storage and use, as well as the gases that may be emitted from the materials surrounding the LED products.

- Corrosive gases include sulfur components in packaging materials such as cardboard, rubber items such as hoses and packing, agricultural chemicals and fertilizers, and halogen components in seawater, bleaches, disinfectants, electrical wire coatings, plastics, and other materials. Also note that halogen components may be present in trace amounts in the atmosphere due to automobile exhaust, factory emissions, volcanic activity, and other factors.

- As a precaution against corrosive gases, store the product in a sealed container or nitrogen displacement desiccator, etc. Also, when designing mounting boards and mounting equipment, avoid using materials that contain components that generate corrosive gases in the materials used or in the surrounding materials, etc.

- When LED products are used in an environment where VOCs are emitted from peripheral components, VOCs that penetrate and adhere to the surface and inside of the LED lens may cause discoloration and affect optical characteristics (VOC stands for Volatile Organic Compounds, a generic term for organic compounds that volatilize in the atmosphere at normal pressure. VOCs are widely used as additives in paints, inks, adhesives, resins, rubbers, etc.). LED products are particularly vulnerable when used in enclosed or confined spaces. In such cases, we recommend that you take care when selecting LED peripheral materials, etc., and conduct a prior inspection of the actual LED fixture, including the LED peripheral materials and the fixture environment.

9. Other Notes and Requests

- The standard warranty period is 12 months from the date of shipment. If a defect is discovered and reported to us within the warranty period, the warranty is limited to repair or replacement of the product. Any further liability is the responsibility of the customer. The warranty does not cover the following, even if the product is still under warranty:

- Malfunction or damage due to careless handling or misuse.

- Malfunction or damage due to improper repair or modification, etc.

- Malfunction or damage due to force majeure such as fire, earthquake, flood, lightning, other natural disasters, pollution, etc.

- Malfunction caused by reasons that could not be foreseen by the technical standards at the time of shipment.

- Defects caused by failure to comply with laws, regulations and safety standards outside Japan other than those separately agreed.

- Our standard products are intended for use in general electronic equipment applications (measuring equipment, communication equipment, office equipment, home appliances, etc.). If you intend to use our standard products in applications other than the above or in special applications (aerospace equipment, transportation equipment, medical equipment, security equipment, nuclear control equipment, etc.) where high reliability and safety are required and failure or malfunction may directly affect human life or health, please contact our sales office in advance.

- In case of use in the above special applications, we will not be liable for any loss or damage resulting from malfunction of our products, unless otherwise specified in the specifications and other documents separately exchanged in advance. In the event of malfunction of our products in the customer’s equipment in which our products are incorporated, please ensure that sufficient safety design is implemented in consideration of possible malfunction so as not to cause extended damage, etc.

- Provide end users of equipment in which our products are incorporated with explanations and appropriate warnings and instructions on the handling of the products and the equipment in which they are used.

- Do not disassemble or reverse engineer this product without our permission. If a defect is found, do not disassemble the product and contact our sales office.

- The examples of use in our materials are typical examples of use and are not intended to warrant suitability for any particular purpose or the success or failure of any commercial use. We do not guarantee or grant any license for the implementation of intellectual property rights, and we assume no responsibility for any intellectual property issues that may arise.

- Unauthorized reproduction or reprinting of the contents of this technical support information and data sheets is prohibited

- Product specifications (form, conditions of use, features, data, notes, etc.) and product appearance described in this technical support information and data sheets are subject to change without notice for product improvement. Although the information in the data sheets has been prepared with the utmost care and accuracy, please note that in the rare event of errors, etc., the information may be corrected without prior notice. Please check the latest data sheet before use.

- When exporting equipment incorporating our products, please comply with the Foreign Exchange and Foreign Trade Law and other export-related laws and regulations.

- Some of our products contain substances that are regulated by waste disposal and public cleaning laws. Please dispose of these products by a specialized waste disposal company.