Through-hole LED

All lamps have a specific “bulb type” designation that describes the shape of the lamp and the size of the lamp (diameter). The designation is a two part code consisting of a letter and a number. The letter indicates the shape of the lamp and the number relates to the diameter of the lamp in eighths of an inch. A “T” designation means “Tubular”, which in the form of a T-1 ¾ lamp became the primary package size for LEDs when they were first introduced and are still a standard form in much demand. . “T-1” is the base designation for a 1/8” diameter lamp, the smallest size “T” lamp. Other designations are based on the T-1 standard, i.e., T-1¾ is 1¾ multiplied by 1/8, or .219”. These were then converted to millimeter, so a T-1¾ is also known as a 5mm lamp.

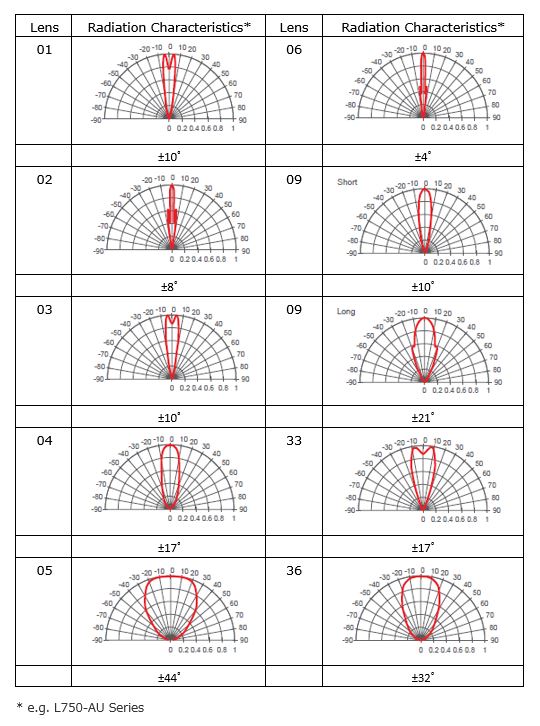

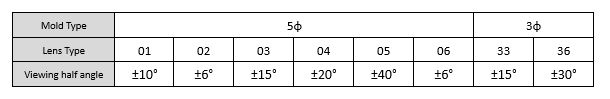

MARUBENI Tech-LED sells 3 and 5mm LED PTH Lamps. The 3mm and 5mm lamps LEDs have different lamp shape and varies view angle you can choose. Once this occurred the diameter of the lamps more closely approximated the mm dimension. Other T-size lamps up to t-10 can be made as custom devices. Please contact us accordingly.

Loading...

Loading...

Through-Hole LED

Tech-LED’s through-hole LEDs provide proven reliability and versatility for applications requiring traditional leaded lamps. We offer standard T-1 (3mm) and T-1¾ (5mm) through-hole LED packages covering ultraviolet, visible, and infrared wavelengths – from UV 365 nm to IR 940 nm, and even specialty near-IR emitters up to 1650 nm. By leveraging UV-resistant epoxy and robust construction, our through-hole lamps maintain stable output over a long lifetime in challenging environments. They feature built-in convex lenses enabling narrow viewing angles as tight as 5°–20° for focused illumination, or wider diffused options for broader coverage. This wide range of lens types offers varied light distributions to suit different needs. Multiple die configurations (e.g. multi-chip and multi-color LEDs) are available in one package, providing unique multi-wavelength outputs or higher intensities from a single through-hole device. We also support custom lead frame designs and form factors to meet specific mounting or integration requirements – demonstrating the custom packaging flexibility of Tech-LED through-hole products.

Key Features and Advantages

- Broad Wavelength Coverage: Tech-LED through-hole lamps span deep UV, visible colors, and IR bands. We supply 365 nm UV LEDs for fluorescence or UV curing, all the way to 850 nm and 940 nm IR emitters for sensing and night-vision, as well as near-IR up to 1650 nm in specialty packages [oai_citation:1‡tech-led.com]. This ensures you can find virtually any wavelength in a through-hole format to meet your design needs.

- High Intensity with Narrow Beams: Our through-hole emitters use efficient chips and optical-grade epoxy lenses to achieve high brightness. Options include narrow-beam LEDs with ±5–10° angles for long-distance illumination or sensors, as well as standard 30–60° lamps for indication and general lighting. A “narrow viewing angle” 1050 nm IR LED, for example, provides concentrated output ideal for optical sensors.

- Rugged and Durable: Through-hole LEDs are physically anchored by their leads, giving them excellent mechanical stability against vibration and shock. The sealed epoxy package is resistant to humidity and environmental stress, making these LEDs a robust choice for outdoor and industrial applications. They operate reliably across a wide temperature range and maintain consistent optical performance over time.

- Easy Integration & Prototyping: The 2-pin through-hole form factor allows simple placement into printed circuit boards (PCBs) or breadboards for prototyping. Long leads accommodate panel mounting or socketing if needed. This makes through-hole LEDs convenient for one-off projects, testing, or retrofit designs. Standard 3mm and 5mm LED lamp sizes ensure compatibility with a variety of indicators, holders, and legacy designs.

Common Applications of Through-Hole LEDs

Through-hole LEDs remain a popular solution for many end-uses thanks to their simplicity and proven performance. In consumer electronics, 5mm indicator LEDs (in red, green, blue, etc.) are used on panels and displays. Infrared through-hole LEDs (typically 850 nm or 940 nm) serve in remote controls and alarm sensors. For example, most TV remote controllers rely on a 940 nm IR LED to transmit signals. In security and surveillance, through-hole IR LEDs are often arranged in arrays (e.g. rings of 5mm IR LEDs around a camera) to provide invisible night illumination. An array of our 850 nm through-hole IR LEDs can flood an area with infrared light that cameras see but humans cannot, enabling CCTV cameras to capture images in total darkness.

Through-hole ultraviolet LEDs (e.g. 375 nm and 395 nm in 5mm packages) are used in counterfeit detection lamps, small UV curing pens, and leak detection lights. Their simple form allows battery-powered UV gadgets for hobbyists and professionals. In automotive and transportation, through-hole LEDs are found in instrument clusters and dashboard indicators due to their reliability under vibration. They are also used in some vehicle ANPR systems and gate sensors – for instance, an 850 nm or 940 nm through-hole IR LED paired with a photodiode can form a break-beam sensor to detect vehicles or count objects.

In smoke detection and safety systems, an IR LED and photodiode in through-hole form create a reliable smoke sensor (the LED emits infrared light into a chamber, and the photodiode monitors for scattered light caused by smoke). Our narrow-beam IR LEDs (e.g. 940 nm in T-1¾ package) are well-suited for this purpose, offering consistent output and easy alignment. Medical devices like pulse oximeters sometimes utilize through-hole dual LEDs (red 660 nm and IR 940 nm together) in clip sensor assemblies to measure blood oxygen – the leads allow secure placement and separation of the two dice.

Overall, Tech-LED’s through-hole series combines an extensive selection of wavelengths (including multi-wavelength options) with the time-tested durability of leaded LED construction. Whether you need a high-intensity IR emitter for a smoke detector, a 365 nm UV through-hole LED for a portable UV lamp, or a simple status indicator, our through-hole lineup delivers dependable performance. We also welcome custom requests – for example, unique lens shapes, atypical T sizes, or multi-chip through-hole modules – to ensure you get the exact through-hole LED solution required for your application.

What is a Through-Hole LED Product?

A through-hole LED product refers to a type of light-emitting diode designed for mounting on printed circuit boards (PCBs) using a hole in the board. These components are characterized by their long leads, which are inserted into the drilled holes and soldered on the opposite side, providing a secure connection.

What is the Technical Specification of Through-Hole LEDs?

The technical specification of through-hole LEDs varies by manufacturer and application. Key specifications include forward voltage, current rating, luminous intensity, and wavelength. These details ensure that the LED performs optimally in its intended application.

How to Select the Right Through-Hole LED Component?

Selecting the right through-hole LED component involves considering factors such as color, size, brightness, and power requirements. It’s important to review the product datasheet to understand the specifications and ensure compatibility with your electronic circuit design.

What Information is Available for Through-Hole LED Part Numbers?

Each through-hole LED part number corresponds to specific characteristics, including color, size, and intensity. Manufacturers provide detailed information about each part number, including its specifications, to help engineers choose the right component for their projects.

Can You Provide a Description of Through-Hole LEDs?

A through-hole LED is a discrete electronic component that emits light when an electric current passes through it. These LEDs are often used in indicator lights, displays, and various lighting applications due to their reliability and ease of use in circuit designs.

What are the Advantages of Using Thru-Hole LEDs in the Industry?

Thru-hole LEDs offer several advantages in the industry, including durability, ease of handling, and better heat dissipation compared to surface-mount LEDs. Their robust design makes them suitable for applications in harsh environments and for prototyping.

What is the Difference Between Through-Hole and Surface-Mount LEDs?

The main difference between through-hole and surface-mount LEDs lies in their mounting technique. Through-hole LEDs use leads that go through holes in the PCB, while surface-mount LEDs are soldered directly onto the surface of the board. This can affect the design, size, and application of the LED.

How Do You Determine the Leg Length for a Through-Hole LED?

Determining the leg length for a through-hole LED depends on the PCB thickness and the desired mounting height. It’s essential to measure the board’s thickness and choose a leg length that allows the LED to sit flush with the board or at the required height for optimal performance.