In the UV curing world, 365 nm is widely recognized as the standard UV-A LED curing wavelength. This specific LED wavelength lies in the long-wave ultraviolet range, delivering “invisible” UV light that triggers photochemical reactions without stray visible glare. From curing inks and coatings to bonding adhesives and hardening 3D printing resins, 365nm UV LEDs drive high-throughput production lines with precision, often utilizing 365nm UV light strips for efficiency. Their popularity stems from a unique balance of spectral purity, deep material penetration, and well-established photoinitiator compatibility – all critical for dose control and consistent process validation in industrial settings.

How Do 365 nm UV LEDs Produce Ultraviolet Light?

The emission wavelength of an LED is fundamentally determined by its semiconductor bandgap energy. In the case of a 365nm UV LED, the device is built on an aluminum-gallium-nitride (AlGaN) semiconductor engineered to emit photons in the ultraviolet range. When current passes through the LED diode, electrons drop into “holes” across the bandgap, releasing energy as UV photons of a specific wavelength. Because LED outputs are not perfectly monochromatic, a typical 365nm UV LED emits a narrow band of light, with most of its output confined to approximately 355–375 nm, which is crucial for effective curing. In practice, this means the device outputs deep ultraviolet light centered at 365 nm using 365nm UV light, rather than any significant visible light.

Unlike fluorescent UV tubes or mercury lamps – which emit broad UV spectra – LEDs produce a tightly centered emission. This spectral purity is a major advantage for UV curing. A 365 nm LED emits almost pure UV-A light with very little visible light content. To the human eye, a 365 nm UV LED’s light appears as a faint, dull violet glow – nearly invisible to the naked eye, since it’s mostly beyond the visible spectrum. (Any faint glow is due to a small amount of visible “leakage” around the 400 nm edge of the output.) The result is an ultraviolet light source that can activate photoinitiators efficiently without adding stray visible wavelengths. For industrial applications, this pure UV output is ideal because it avoids interfering with vision systems or causing unwanted curing of materials that might respond to visible violet light.

365 nm vs 395 nm UV LEDs: What’s the Difference?

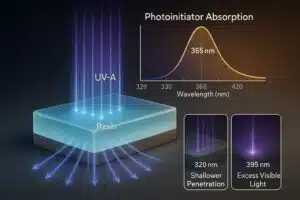

Users often ask about the difference between 365 nm and 395 nm UV LEDs, since both are common in the UVA range. The primary difference is spectral output and visible light content. A 395 nm LED operates closer to the border of visible light (~400 nm), so it emits a pronounced purple glow that is easy to see. In other words, a larger portion of the 395nm spectral output falls within the visible violet region, impacting its application as a UV flashlight. By contrast, a 365 nm LED is deeper in the ultraviolet and produces much less visible light. Its light appears as a dull, dim violet (almost invisible), making it a true “black light” source. This difference is critical in applications like UV curing and fluorescent inspection. The 365 nm wavelength LED provides a more pure UV output with less visible interference, whereas 395 nm LEDs trade some UV purity for higher raw optical power.

Indeed, at the component level, 395nm LEDs can often drive higher radiant flux than 365nm UV LEDs – primarily due to material science and quantum efficiency factors.. According to one technical study, a 395 nm UV LED lamp delivered roughly ten times the peak irradiance of a comparable 365 nm lamp [oai_citation:0‡pcimag.com](https://www.pcimag.com/articles/99100-uvled-photoinitiator-and-cure-study#:~:text=Note+that+a+395+nm,Considering). However, that extra power comes with a trade-off: the emission includes a small amount of visible violet light. For industrial UV curing processes, 365 nm remains the preferred choice for most UV-A applications because its invisible spectrum output avoids glare and maximizes photoinitiator activation without exciting pigments or dyes that respond to visible light. Many commercially available UVA light systems use 365 nm as the standard curing wavelength, while 395 nm LEDs are more often found in low-cost 405 nm/395 nm UV LED flashlights and 365 nm LED strip light products where some visible “blacklight” effect is desirable.

UV Curing Fundamentals: Irradiance vs. Energy Dose

Successful UV curing depends on delivering the right amount of light energy to a material within a given process window. Two key metrics are irradiance and energy dose. Irradiance (measured in mW/cm²) is the intensity of UV light hitting the target at any moment – essentially the power per unit area. Energy dose (measured in J/cm²) is the total accumulated energy delivered over the exposure time (irradiance multiplied by time). A 365 nm LED curing system must provide sufficient irradiance to initiate rapid polymerization (for example, hundreds of mW/cm² on the surface) and a sufficient dose to fully cure the material through its depth (often several J/cm² in total).

It’s important to distinguish between peak irradiance and total dose. Some UV processes require a high peak (to kick off a fast cure or penetrate through pigmented layers), while others rely on a longer exposure to build up energy. Engineers must balance these parameters to ensure the photoinitiators receive the minimum energy dose for full cure, without overexposure that could cause overheating or material degradation. The relatively narrow output spectrum of a UV LED (compared to a broad-spectrum mercury lamp) means formulators often tune photoinitiator packages to match that specific 365 nm output. Process validation usually involves measuring both irradiance and dose using calibrated radiometers or optical sensors to ensure consistent production quality.

Photoinitiators and Materials: Depth of Cure at 365 nm

Cross-Section Diagram of Photoinitiator Absorption at 365 nm

UV-curable materials (inks, coatings, adhesives, etc.) rely on chemicals called photoinitiators, which absorb 365nm UV photons and generate reactive species that start polymerization.. Photoinitiators have specific absorption spectra, and many common initiators are designed to absorb strongly in the UV-A range around 365 nm. In fact, a recent polymer science review noted that most commercial photoinitiators are sensitive to UV light and cannot be optimally activated under longer visible wavelengths [oai_citation:1‡pubmed.ncbi.nlm.nih.gov](https://pubmed.ncbi.nlm.nih.gov/36679223/#:~:text=Currently%2C+increasing+attention+has+been,Many) – one reason 365 nm LED sources remain so important. When a 365 nm UV LED shines on a resin that contains the right photoinitiator, it efficiently triggers the curing reaction. By contrast, a 395 nm or 405 nm LED might not excite certain photoinitiators enough unless the formulation has been adjusted (or special photoinitiators added) for those longer wavelengths.

The 365 nm wavelength also offers a good balance between surface cure and depth cure. Shorter UV wavelengths (closer to the UV-B range) can initiate extremely fast surface polymerization but may be largely absorbed at the surface, leading to a phenomenon called “surface vitrification” – the top layer hardens too quickly and blocks further UV penetration beneath. Longer UVA wavelengths like 365 nm penetrate deeper into clear or lightly pigmented materials, reducing the risk of an undercured tacky layer beneath a fully hardened surface. Additionally, many photoinitiators that work at 365 nm are optimized for low yellowing, so the cured product remains clear. For very thick or heavily pigmented systems, sometimes a combination of photoinitiators is used – some that absorb at 385–395 nm for depth, and others at 365 nm for surface cure – or a two-step curing process is employed. One study found that the best results were obtained by exposing a coating to 395 nm light first for deeper penetration, then following with 365 nm UV to fully cure the surface [oai_citation:2‡pcimag.com](https://www.pcimag.com/articles/99100-uvled-photoinitiator-and-cure-study#:~:text=To+test+this+principle%2C+a,light+to+facilitate+surface+cure). This kind of hybrid strategy highlights why 365 nm remains indispensable: it reliably cures surface layers and finishes the polymerization that longer wavelengths start.

Packaging and Thermal Management in 365 nm LED Systems

Driving a high-power 365 nm LED to the intensities required for industrial curing (often several watts of optical output) generates significant heat. Thermal management is absolutely critical because the performance and longevity of UV LEDs are highly temperature-sensitive. As a 365 nm LED’s junction temperature rises, its light output can drop and its peak wavelength may shift slightly to a longer nm value. To mitigate this, manufacturers use advanced package designs and materials. For instance, chip-on-board (COB) designs are often utilized in 365nm UV LED applications.COB (Chip-on-Board)) UV LEDs mount multiple LED chips directly on a thermally conductive substrate, spreading heat efficiently. Many modern UVA LED chips are driven at 500–700 mA, often dissipating 1–3 W of input power each in exchange for high ultraviolet output. High-power surface-mount devices like High-power SMBB packages and the ceramic-based High-power EDC packages are also engineered to handle the thermal loads of UVA LEDs by using materials with high heat conductivity and by maximizing the surface area for heat sinking.

In a production UV curing lamp, the LED packages are mounted on metal-core PCBs or directly onto heatsinks. Active cooling (fans or water) keeps junction temperatures in safe limits and ensures stable output. Many systems also include over-temperature shutoffs to protect the LEDs. With proper thermal design, 365 nm LEDs deliver consistent performance over a long lifetime (often tens of thousands of hours to L70). Using robust packages and ample heat sinking, industrial UV LED sources can run reliably around the clock.

Optics and System Integration for Uniform UV Curing

Delivering UV light uniformly and efficiently to the target is another engineering challenge in UV-A LED curing systems. Because LEDs are directional light sources, secondary optics are used to shape and distribute the 365 nm output as needed. Common solutions include lens arrays, UV-transparent light guides, and reflective cavities. For example, each LED in a module may have an integrated lens to widen its beam, or an external cylindrical lens might focus the UV light into a line across a conveyor. Reflectors with UV-specialized coatings can also redirect and concentrate the LED emissions. All optics must be made of materials that transmit UVA (such as fused silica or UV-grade acrylic), since ordinary glass would absorb too much of the 365 nm light.

In system integration, one must consider the working distance (the gap between the UV LED lamp and the product surface). UV intensity decreases with distance according to the inverse-square law, so even a few extra centimeters of gap can significantly lower the irradiance. High-power 365 nm LED curing systems often position the lamp as close as possible to the substrate – sometimes only a few millimeters away – especially in conveyor setups. However, distance and angle are optimized to achieve uniform coverage. Many systems use arrays of LEDs (arranged like a 365nm LED strip or matrix) to cover wide areas and ensure even illumination across the entire target. These UV light fixtures can also be tiled or staggered to scale up for larger curing widths. Additionally, for safety, most curing units include enclosures or shielding; any viewing ports use UV-blocking glass, and interlock switches prevent the UV source from operating when access doors are open. In short, careful optical design and integration are key to providing a uniform, high-intensity UV-A exposure on the product for consistent curing results.

Measuring UV Intensity and Ensuring Quality

Maintaining a validated process requires regular monitoring of the UV output. Engineers use radiometry tools to ensure the 365 nm intensity stays within spec – for example, handheld radiometers can measure mW/cm² at the cure surface, and some systems integrate reference photodiodes to continuously check LED output. Quality assurance procedures often include routine dose checks on test samples or use of dosimeter strips to confirm that every area (center and edges) receives sufficient energy. By correlating these measurements with cure outcomes (hardness, adhesion, etc.), manufacturers can detect any drop in lamp performance (due to LED aging or dirty optics) and service the equipment before product quality is impacted.

Safety and Compliance When Working with 365 nm UV Light

Although UVA is the least energetic form of ultraviolet radiation, high-intensity 365 nm sources still pose safety risks that must be managed. According to the IEC 62471 photobiological safety standard, powerful UV-A LED lamps are classified as Risk Group 3 devices (highest hazard category) – meaning even momentary direct exposure can be hazardous to eyes or skin. Thus, engineering controls and personal protective equipment are mandatory in UV curing environments. At the system level, UV curing units are often designed with interlocked enclosures or shields that prevent operators from seeing the UV light directly or placing skin in its path. Any necessary viewing windows are made of UV-blocking transparent material. Warning labels (e.g. “UV emitted from this product” and “Avoid eye/skin exposure”) are placed on the equipment per standard requirements.

Workers must wear appropriate PPE when operating or servicing UV curing equipment. This typically includes UV-rated eyewear (e.g. yellow polycarbonate safety glasses that block 365 nm) and coverage for any exposed skin (gloves, long sleeves). Occupational exposure guidelines, such as those from ACGIH, recommend limiting UVA irradiance to about 1.0 mW/cm² for any exposure longer than 1,000 seconds (around 16 minutes) [oai_citation:3‡ccohs.ca](https://www.ccohs.ca/oshanswers/phys_agents/ultravioletradiation.html#:~:text=Many+jurisdictions+follow+the+limits,ACGIH%2C+2025) – a level easily exceeded by industrial 365 nm curing lamps that often output several W/cm². Therefore, administrative controls (like time limits on exposure) alone are not sufficient; well-designed shielding and strict PPE protocols are essential to ensure a safe work environment when using UV LED light.. In summary, compliance with photobiological safety standards (e.g. IEC 62471) and adherence to best practices for UV safety are critical parts of deploying 365nm UV LED curing systems.

Applications of 365 nm UV LED Curing in Industry

The 365 nm UV LED has become a workhorse across a range of industrial applications where rapid, on-demand curing is needed without excessive heat. Notable use cases include:

- Electronics & PCB Assembly: UV-curable conformal coatings on circuit boards and potting compounds for electronic modules are cured with 365 nm LED systems to quickly protect components without thermal stress.

- Medical Devices: Catheter bonding, syringe sealing, and potting of sensitive electronics or optics in medical devices often leverage UVA LED curing for precision and material compatibility (many medical-grade adhesives are formulated for 365 nm).

- Adhesives & Optical Bonding: Fiber-optic connectors, glass-to-metal bonds, and structural adhesives in manufacturing can be cured in seconds with 365 nm light, ensuring alignment isn’t disturbed by long cure times.

- Coatings & Inks: Industrial wood finishes, automotive clearcoats, and printing inks (especially in high-speed digital inkjet printing) use 365 nm UV LEDs to achieve fast drying and hardening. The lack of excess heat allows curing on heat-sensitive substrates like plastics and composites.

- 3D Printing (Additive Manufacturing): Some stereolithography (SLA) and DLP 3D printers employ 365 nm or mixed-wavelength UV LED sources to cure photopolymer resins layer by layer. The 365 nm light can provide deeper penetration for certain resin chemistries, complementing 405 nm LEDs to ensure complete polymerization.

When to Consider 405 nm LEDs or Multi-Wavelength Arrays

While 365 nm is the dominant UV-A curing wavelength, there are scenarios where 405 nm or other UVA wavelengths (e.g. Both 365nm and 395nm are considered. One reason is intensity: as mentioned, 395–405 nm LEDs can offer higher power output and sometimes lower cost per milliwatt, which might tempt engineers to use them if the material’s chemistry permits. In applications where a slightly longer wavelength can still activate the photoinitiators (for example, some modern formulations include photoinitiators designed for up to 405 nm), using 385+ nm LEDs can increase curing speed or allow greater working distance. A multi-wavelength array – combining, say, 365 nm and 395 nm LEDs in one curing head – can also provide a broader spectral range, more closely mimicking the output of a mercury arc lamp. This approach helps ensure that blends of photoinitiators (each with different peak sensitivities) are all sufficiently triggered.

However, shifting to 405 nm comes with caveats. Standard photoinitiators may not be activated efficiently at 405 nm unless the formulation is adjusted, and the LED’s visible purple output can inadvertently affect vision systems or light-sensitive components. For these reasons, most UV systems still rely on 365 nm for the majority of the cure, using 385–405 nm LEDs only as supplements when needed for extra depth. Field studies have even shown that a sequential cure (395 nm exposure followed by 365 nm) can maximize polymerization in difficult formulations [oai_citation:4‡pcimag.com](https://www.pcimag.com/articles/99100-uvled-photoinitiator-and-cure-study#:~:text=To+test+this+principle%2C+a,light+to+facilitate+surface+cure). Overall, multi-wavelength arrays are useful for certain niche cases, but 365 nm remains the primary UV-A workhorse in most applications.

Next Steps: Selecting the Right 365 nm UV LED Solution

For technical managers evaluating a 365 nm UV LED curing system, a few practical considerations can guide the selection:

- Wavelength Fit: Verify that your material’s photoinitiators are responsive at 365 nm (check initiator absorption spectra or consult your formulation supplier). Standard UV-curable formulations are usually optimized for this wavelength, since 365 nm has long been an industry staple.

- Required Intensity and Dose: Determine the irradiance and total energy dose needed for full cure within your desired cycle time. This will dictate how powerful a lamp (or how many LED modules) you need. It also informs cooling requirements, as higher-power systems will generate more heat.

- Uniformity and Scaling: Consider the size of the area to cure with the appropriate 365nm UV LED light. For small spots or individual components, a single LED lamp head might suffice. For larger surfaces or high-throughput conveyors, look for modular lamp designs that tile multiple 365nm UV LED emitters to cover the area uniformly without gaps.

- Thermal Management: Ensure the system has adequate cooling and that its specifications (ambient operating limits, heatsink requirements) match your operating environment. A well-cooled 365nm UV LED system will maintain consistent wavelength and output over long production runs, and will last longer than traditional bulbs.

- Controls and Monitoring: Features like adjustable output intensity, shuttering capability, and integrated radiometers or photodiodes for feedback can be valuable for process control. Such features help in fine-tuning exposure and quickly detecting any deviation in UV LED light output.

- Safety & Compliance: Verify that the system includes proper safety measures (interlocks, shielding) and comes with relevant certifications or testing to IEC standards. Plan for operator training, UV safety signage, and personal protective equipment as part of the implementation.

By reviewing these factors, you can shortlist UV LED curing solutions that best match your application’s technical requirements and operational constraints. As you explore options, you may find it useful to consult broader resources on UV LED technology. For instance, our UV & Near-UV LEDs (235–420 nm) product page provides an overview of available UV LED options, and our LED wavelength guide explains how various wavelengths (from ultraviolet to infrared) are applied across different applications. You can also dive into specific topics like our in-depth look at 405 nm LEDs, the nuances of UV-C LEDs for germicidal purposes, or the uses of 660 nm deep-red LEDs and SWIR LEDs in specialized sensing. With the right knowledge in hand, you’ll be well-equipped to implement a 365 nm UV LED solution that delivers on curing performance, efficiency, and safety.

Q: What is the difference between 365nm and 395nm UV LED lights?

A: The main difference lies in their wavelengths; 365nm UV LED emits light that is closer to the ultraviolet spectrum and is more effective for curing applications, while 395nm UV LED light has a small amount of visible “leakage,” which makes it appear purple and is often used for black light effects.

Q: What applications are best suited for 365nm UV LED lights?

A: 365nm UV LED lights are ideal for curing inks, adhesives, and coatings due to their effective black light and curing effects. They are also used in UV LED light strips for various applications, including fluorescence testing and sanitation.

Q: Can I use a flashlight 365nm for detecting fluorescent materials?

A: Yes, a flashlight 365nm is highly effective for detecting fluorescence in various materials. The ultraviolet light emitted enhances the visibility of fluorescent materials, making them glow brightly under the 365nm wavelength.

Q: Are 365nm UV LEDs safe to use for prolonged periods?

A: While 365nm UV LEDs are generally safe, it is advisable to avoid direct skin exposure and prolonged eye contact, as UV radiation can cause skin burns and eye damage. Always use protective gear when working with UV light.

Q: What types of light fixtures can accommodate 365nm UV LED strips?

A: 365nm UV LED strips can be used in various light fixtures, including standard lamps, specialized UV curing systems, and custom light setups designed for ultraviolet applications.

Q: How does the intensity of 365nm UV light compare to 395nm in terms of curing?

A: The intensity of 365nm UV light is generally more effective for curing materials compared to 395nm. The 365nm wavelength produces stronger black light and curing effects, making it preferable for industrial and professional applications.

Q: What is the voltage requirement for 365nm UV LED strips?

A: Most 365nm UV LED strips operate on DC 12V power. It is essential to ensure that your power supply matches this specification to avoid damage to the LED strip.

Q: Do 365nm UV LED lights produce any heat during operation?

A: Yes, 365nm UV LED lights can produce some heat during operation, but they are generally more efficient and produce less heat than traditional UV lamps. It is recommended to allow for proper ventilation when using high-intensity UV LEDs.

Q: Can I replace a traditional UV lamp with a 365nm UV LED bulb?

A: Yes, you can replace traditional UV lamps with 365nm UV LED bulbs, which provide longer life, lower energy consumption, and less heat output. However, ensure that the application requirements match the characteristics of the LED bulb.